Inkunkuma yeglasi luhlobo lwenkunkuma yasekhaya, ubukho bayo abubangeli nje ingozi kunye nokuphazamiseka kwimveliso kunye nobomi babantu, kodwa izisa ungcoliseko kwendalo, ithatha umhlaba oxabisekileyo, kwaye yandisa umthwalo wokusingqongileyo.Kuqikelelwa ukuba i-China ivelisa malunga ne-3.2 yezigidi zeetoni zeglasi yenkunkuma minyaka le, ibalwa malunga ne-2% yexabiso lilonke lenkunkuma eqinileyo kamasipala.Ngokwandiswa kwamandla abanzi esizwe kunye nokuphuculwa komgangatho wokuphila kwabantu, isixa sisonke seglasi yenkunkuma siye sanyuka.Ngokubhekiselele ekuhlaziyweni nasekusetyenzisweni kweeglasi ezilahliweyo, amanye amazwe aphuhlileyo eUnited Kingdom naseUnited States aye afumana iziphumo ezimangalisayo.Amazwe aseYurophu naseMelika asebenzise ngempumelelo iglasi yenkunkuma kwiiprojekthi zokwakha, eyindlela esebenzayo yokusebenzisa isixa esikhulu seglasi yenkunkuma.Ngenxa yokuba zonke iintlobo zeglasi yenkunkuma ayifuni kuhlengahlengiswa, akukho mfuneko yombala.Umzekelo, inkunkuma yeglasi icutshungulwa njengesixhobo sokuhlobisa isakhiwo kwiMosaic.Njengomenzi weglasi yokusila eyinkunkuma, inkunkuma yeglasi yokusila eveliswe yiHCM Machinery ibonelela ngoncedo lwesixhobo esilungileyo sokuphinda kusetyenziswe inkunkuma yeglasi.Namhlanje, siza kwazisa inkqubo yokuvelisa inkunkuma yeglasi yokuphinda isetyenziswe kwiglasi kaMosaic.

1. Ukuzuzwa kwelitye lephosphate: Ukuxhamla kwilitye lephosphate linyathelo lokuqala ekusetyenzweni kwelitye lephosphate, elijolise ekwahluleni iiminerali eziluncedo kubumdaka obukwilitye lephosphate ngeendlela zomzimba nezemichiza.Iindlela eziqhelekileyo zokuzuza zibandakanya ukwahlula umxhuzulane, ukuphaphatheka kunye nokwahlula kumagnethi.Ukwahlulahlula komxhuzulane kusebenzisa umahluko woxinaniso lweeminerali kwintsimbi ekrwada ukuze yahlulwe, ukuphaphatheka kusebenzisa umahluko wokunyuka kwezimbiwa kwintsimbi ekrwada ukwenzela ukwahlula, kwaye ukwahlula kumagnethi kusebenzisa umahluko wemagnethi weminerali kwintsimbi ekrwada ukwahlula.

2. Ukutyunyuzwa kunye nokusila i-phosphate rock: i-phosphate rock emva kwe-beneficiation, idinga ukutyunyuzwa kunye nokusila unyango, ukuze kukhululwe ngcono iiminerali eziluncedo kwi-ore.Ukutyumza kudla ngokusetyenziswa isityumzi somhlathi, isityumzi sekhowuni kunye nezinye izixhobo zokuqhekeza iliwa lephosphate ibe yisayizi yamasuntswana afanelekileyo.Ukusila kukusetyenziswa kwemveliso enkulu yokusila kunye nokulungiswa komatshini womgubo wephosphate ukucolisisa intsimbi ekrwada etyunyuziweyo, ukuze ihlangabezane neemfuno zokucoleka ezifunekayo.

3. Ukuphuma kwelitye lephosphate: Ukuvuza linyathelo eliphambili ekusetyenzweni kwelitye lephosphate, apho izithako eziluncedo ezifana nephosphate inokunyibilika kwintsimbi ekrwada.Iindlela ezixhaphakileyo zokuvuza zibandakanya ukuvuza kweasidi, ukuvuza kwealkali kunye ne-oxidation leaching.Ukuvuzwa kweasidi kusebenzisa isisombululo esineasidi ukunyibilikisa iphosphate, ukuvuza kwealkaline kusebenzisa isisombululo sealkaline ukunyibilikisa iphosphate, kwaye i-oxidative leaching isebenzisa i-oxidizing agent ukunyibilikisa iphosphate.

4. Imvula kunye nokuhluzwa kwe-phosphate ores: Emva kokuvuthwa, isisombululo samacandelo aluncedo afana ne-phosphate kufuneka ihlanjululwe kwaye ihluzwe ukwahlula iimveliso eziqinileyo ze-phosphate.Imvula kukusetyenziswa kwe-agent ye-precipitating ukuguqula icandelo le-phosphate yesisombululo kwi-precipitate eqinile, kwaye ukuhluza kukwahlulwa kwentlenga kwisisombululo ngezixhobo zokucoca.

5. Ukomiswa kunye nokuntywila kwelitye lephosphate: Emva kokuba intlenga ihluziwe, kufuneka yomiswe kwaye ifakwe emanzini ukuze kufumaneke imveliso yephosphate egqityiweyo.Ukomisa kukusetyenziswa kwezixhobo zokomisa ukwenza amanzi abe ngumphunga kwintlenga, kwaye ukomisa kukomisa intlenga kwiqondo lobushushu obuphezulu, ukuze yenze amasuntswana axineneyo ephosphate.

6. Ukunyangwa kwe-phosphate ore tailings: inkqubo yokucubungula i-phosphate ore iya kuvelisa inani elithile le-tailings, i-tailings iqulethe iiminerali ezingaxutywanga kunye nokungcola.Ukuze kuncitshiswe ukungcoliseka kwendalo kunye nokuchithwa kwemithombo yobutyebi, iintsila kufuneka zinyangwe.Iindlela eziqhelekileyo zokunyanga iintsalela zezimbiwa ziquka ukupakishwa kweentsalela zezimbiwa, ukurisayikilishwa kweentsalela zezimbiwa kunye nokusetyenziswa ngokubanzi.

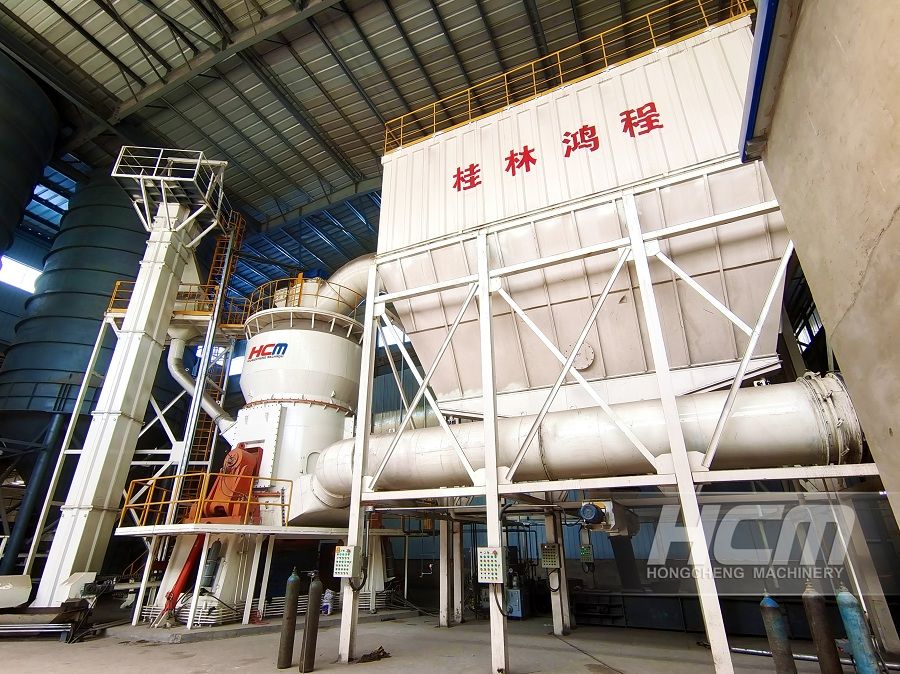

Inkqubo yemveliso yeglasi egayiweyo yokurisayikilisha yeglasi IMosaic: indlela yokuntywila kunye nendlela yokunyibilika isetyenziswa ngokubanzi, kwaye indlela yokuvelisa yendlela ye-sintering kunye ne-ceramic Mosaic ziyafana ngokusisiseko.Eyona nkqubo iphambili yemveliso kukugaya iglasi yenkunkuma ngokusebenzisa inkunkuma yeglasi yokusila ukuhlangabezana neemfuno zokulunga komgubo weglasi, uze wongeze inani elithile le-agent encangathi (i-inorganic okanye i-organic can) kunye ne-arhente yombala okanye i-agent decolorizing, kunye i-mixer ukuyixuba ibe yinto efanayo.Lo mxube ucinezelwe kwiimilo ezahlukeneyo zejiyometri ngendlela eyomileyo yokucinezela, kwaye umzimba owomileyo uthunyelwa kwi-roller kiln, ipuleti yokutyhala kunye ne-tunnel kiln kunye nobushushu obungama-800-900 degrees Celsius ukwenzela ukutshisa.Ngokuqhelekileyo, ihlala kwindawo yokushisa ye-sintering ye-1.5-2.5 iiyure.Iimveliso zokupholisa ngaphandle kwe-oven ukuze zihlolwe, zibekwe, zomiswe, zihlolwe, zipakishwe, zigcinwe okanye zifakwe kwifektri, iimveliso ezingafanelekanga ziphinda zisetyenziswe.Indlela yokunyibilika isekelwe kwiglasi yenkunkuma (inani labantu li-25-60%) njengeyona nto iphambili ekrwada, yongeza inani elithile lesanti ye-silica, i-feldspar, i-limestone, i-soda ash kunye ne-emulsion agent, i-agent yombala ngokusebenzisa i-glass grinding. indlela ibe ngumgubo ohambelanayo ofanayo, kwaye emva koko kwi-oven enyibilikayo yobushushu obuphezulu (iqondo lokunyibilika liyi-1400-1500) ukunyibilika kulwelo lweglasi efanayo.Ulwelo lweglasi luqukuqela kwikhalenda kwaye lucinezelwe kwibhloko yeglasi yobungakanani obuthile kunye nokumila, ethi ithunyelwe kwi-annealing kiln.Iimveliso ezifakwe kwi-anneal zingagcinwa okanye zihanjiswe emva kokuhlolwa, ukubekwa kunye nokupakishwa.

Inkunkuma yeglasi yokurisayikilisha Imizobo yeglasi isekwe ekusileni inkunkuma yeglasi ibe ngumgubo weglasi.Inkunkuma yeglasi yokusila sisixhobo sokuvelisa umgubo weglasi.Inkunkuma yeglasi yokusila eveliswe nguHCM oomatshini has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Ixesha lokuposa: Jan-08-2024