Ugegbe mkpofu bụ ụdị ihe mkpofu ụlọ, ịdị adị ya abụghị naanị na ọ na-akpata mmerụ na adịghị mma na mmepụta na ndụ mmadụ, kamakwa ọ na-ebute mmetọ na gburugburu ebe obibi, na-eburu ala bara uru ma na-abawanye ibu gburugburu ebe obibi.A na-eme atụmatụ na China na-emepụta ihe dị ka nde tọn 3.2 nke iko mkpofu kwa afọ, na-aza ihe dị ka 2% nke mkpokọta mkpofu siri ike nke ime obodo.Site na nkwalite nke ike mba zuru oke na nkwalite nke ụkpụrụ ibi ndụ ndị mmadụ, mkpokọta iko mkpofu abawanyela.N'ihe gbasara imegharị na iji iko mkpofu eme ihe, ụfọdụ mba mepere emepe na United Kingdom na United States enwetala ọmarịcha ihe.Mba Europe na America ejirila iko mkpofu mee ihe nke ọma n'ọrụ ihe owuwu, nke bụ ụzọ dị irè isi rie nnukwu iko mkpofu.N'ihi na ụdị iko mkpofu niile adịghị mkpa ka edozi ya, ọ dịghị mkpa maka agba.Dịka ọmụmaatụ, a na-edozi iko mkpofu dị ka ihe eji achọ ụlọ na Mosaic.Dị ka onye na-emepụta igwe ihe igwe ihe mkpofu, igwe ihe igwe ihe mkpofu nke HCM Machinery na-enye na-enye aka dị mma maka imegharị iko ihe mkpofu.Taa, anyị ga-ewebata usoro mmepụta nke iko mkpogharị iko Mosaic.

1. Uru nke nkume phosphate: Uru nke nkume phosphate bụ nzọụkwụ mbụ na nhazi nke nkume phosphate, nke na-achọ ikewapụta mineral bara uru na adịghị ọcha dị na nkume phosphate site na usoro anụ ahụ na nke kemịkal.Ụzọ a na-enwetakarị uru gụnyere nkewa ike ndọda, flotation na nkewa magnetik.Nkewa ike ndọda na-eji ọdịiche njupụta nke mineral dị na ore maka nkewa, flotation na-eji ihe dị iche iche nke mineral dị na ore maka nkewa, na nkewa magnetik na-eji ọdịiche magnetik nke mineral na ore maka nkewa.

2. Nchicha na ichikota nkume phosphate: nkume phosphate mgbe e nwetasịrị uru, ọ dị mkpa ka a gwerie ya ma na-egweri ọgwụgwọ, iji mee ka ọ dị mma ịhapụ mineral bara uru na ore.A na-ejikarị ihe nhịhịa agba, cone crusher na akụrụngwa ndị ọzọ agbaji nkume phosphate n'ime nha urughuru kwesịrị ekwesị.Egweri bụ iji nnukwu igwe na-emepụta ihe na nhazi phosphate ntụ ntụ na-egweri ọka a zọpịara nke ọma, nke mere na ọ na-emezu ihe achọrọ dị mma.

3. Ntucha nkume phosphate: Ịcha mmiri bụ nzọụkwụ dị mkpa na nhazi nke nkume phosphate, nke a na-esi na ya gbazee ihe ndị bara uru dị ka phosphate na ọla.Ụzọ leaching ndị a na-ejikarị gụnyere acid leaching, alkali leaching na oxidation leaching.Acid leaching na-eji ngwọta acidic gbazee phosphate, alkaline leaching na-eji ngwọta alkaline agbaze phosphate, na oxidative leaching na-eji ihe na-eme ihe na-eme ka ọ gbazee phosphate.

4. Mmiri ozuzo na nzacha nke phosphate ores: Mgbe leaching, ihe ngwọta nke ihe bara uru dị ka phosphate dị mkpa ka a na-eme ka ọ dị elu ma kpochaa iji kewaa ngwaahịa phosphate siri ike.Mmiri ozuzo bụ iji ihe na-emepụta ihe na-emepụta ihe iji gbanwee akụkụ phosphate nke ngwọta n'ime mmiri siri ike, na nzacha bụ nkewa nke sedimenti na ngwọta site na nzacha akụrụngwa.

5. Nhicha na nsị nke nkume phosphate: Mgbe a na-ehichapụ sedimenti ahụ, ọ dị mkpa ka a mịrị amị ma mee ka ọ dị nro iji nweta ngwaahịa phosphate emechara.Ịkpọ nkụ bụ iji akụrụngwa ihicha na-ekpochapụ mmiri dị na sedimenti, na sintering bụ ihicha nke sedimenti na nnukwu okpomọkụ sintering, nke mere na ọ na-etolite nnukwu phosphate particles.

6. Ọgwụgwọ ọdụdụ phosphate: phosphate ore nhazi usoro ga-emepụta ọnụ ọgụgụ ọdụdụ, ọdụ ọdụ nwere mineral na-adịghị amịpụta na adịghị ọcha.Iji belata mmetọ gburugburu ebe obibi na ịla n'iyi, ọ dị mkpa ka a gwọọ ọdụdụ.Ụzọ ọgwụgwọ ọdụdụ a na-ahụkarị gụnyere ikpokọta ọdụdụ, imegharị ọdụ ọdụ na iji ọdụ zuru oke.

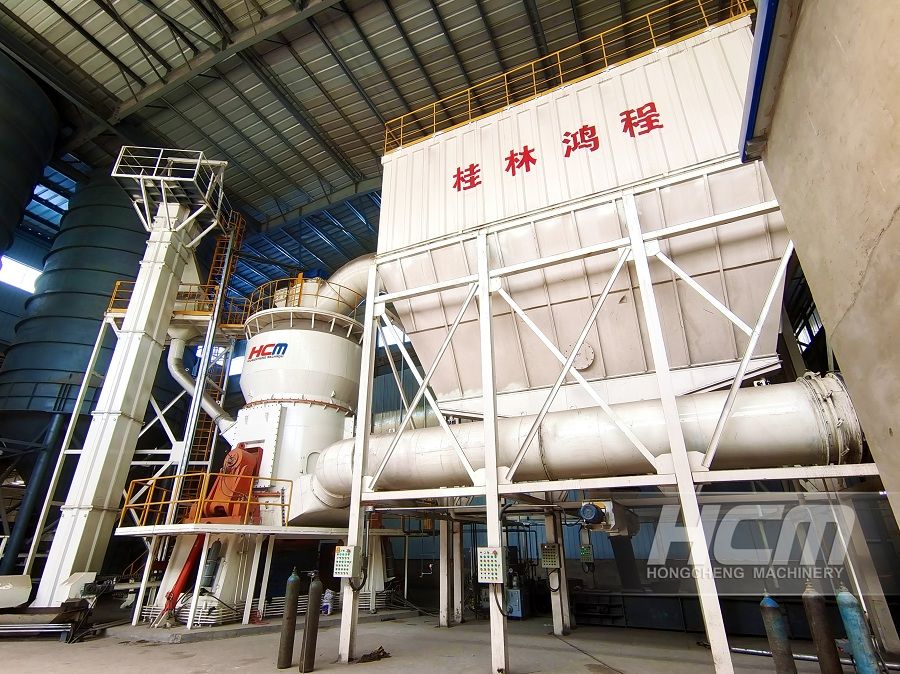

Usoro mmepụta nke iko ihe mkpofu ihe eji emegharị ihe Mosis: usoro sintering na usoro ịgbaze ka a na-ejikarị eme ihe, na usoro mmepụta nke usoro sintering na seramiiki Mosaic bụ otu ihe ahụ.Usoro mmepụta bụ isi bụ ịkwanye iko ihe mkpofu site na igwe igwe ihe mkpofu iji zute ịdị mma chọrọ nke ntụ ntụ iko ahụ, wee gbakwunye otu ego nke nnyapade (inorganic ma ọ bụ organic nwere ike) na onye na-agba agba ma ọ bụ onye na-emepụta ihe, yana igwekota ka mix ya n'ime otu ngwakọta.A na-agbanye ngwakọta ahụ n'ụdị geometric dị iche iche site na usoro ịpị nkụ, a na-eziga ahụ mịrị amị na ebe a na-akpụgharị ihe, akwa efere efere na oghere ọwara na okpomọkụ nke 800-900 degrees Celsius maka sintering.N'ozuzu, ọ na-anọ na mpaghara okpomọkụ na-ekpo ọkụ maka awa 1.5-2.5.Ngwaahịa dị jụụ na-esi na kiln maka nyocha, ntinye, ihicha, nyocha, nkwakọ ngwaahịa, nchekwa ma ọ bụ ụlọ ọrụ mmepụta ihe, a na-emegharị ngwaahịa na-erughị eru.Usoro agbaze na-adabere na iko mkpofu (ọnụọgụ ndị mmadụ bụ 25-60%) dị ka isi akụrụngwa, na-agbakwunye ụfọdụ ájá silica, feldspar, limestone, soda ash na emulsion agent, onye na-agba agba site na igwe ihe mkpofu ahịhịa. usoro n'ime otu ụdị dabara ntụ ntụ, wee banye n'ime nnukwu okpomọkụ agbaze kiln (na-agbaze okpomọkụ bụ 1400-1500) na-agbaze n'ime otu edo iko mmiri mmiri.Mmiri mmiri na-asọba n'ime calender ma tinye ya n'ime otu iko iko nke otu nha na ọdịdị, nke a na-ezigara na kiln annealing.Enwere ike ịchekwa ngwaahịa annealed ma ọ bụ nyefee ya mgbe nyochachara, ntinye na nkwakọ ngwaahịa.

Ntugharị iko ihe mkpofu ihe mosaics Glass gbadoro ụkwụ na-egweri iko mkpofu ka ọ bụrụ ntụ ntụ iko.Igwe igwe ihe mkpofu bụ akụrụngwa mmepụta maka nhazi uzuzu iko.Igwe igwe ihe mkpofu na-emepụta site naIgwe HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Oge nzipu: Jan-08-2024