Magalasi a zinyalala ndi mtundu wa zinyalala zapakhomo, kukhalapo kwake sikumangobweretsa zovulaza komanso zosokoneza pakupanga ndi moyo wa anthu, komanso kumabweretsa kuipitsa chilengedwe, kumatenga malo amtengo wapatali, ndikuwonjezera chilengedwe.Akuti China imapanga pafupifupi matani 3.2 miliyoni a galasi lotayirira chaka chilichonse, zomwe zimawerengera pafupifupi 2% ya kuchuluka kwa zinyalala zolimba zamatauni.Ndi kupititsa patsogolo mphamvu za dziko lonse komanso kusintha kwa moyo wa anthu, kuchuluka kwa magalasi otayira nawonso kwawonjezeka.Pankhani yokonzanso ndi kugwiritsira ntchito magalasi otayira, mayiko ena otukuka ku United Kingdom ndi United States apeza zotsatira zabwino kwambiri.Mayiko a ku Ulaya ndi ku America agwiritsa ntchito bwino magalasi otayira pa ntchito yomanga, yomwe ndi njira yabwino yowonongera magalasi otayira ambiri.Chifukwa mitundu yonse ya magalasi otayika safunikira kusanjidwa, palibe chofunikira pamtundu.Mwachitsanzo, magalasi otayira amakonzedwa ngati zokongoletsa zomanga mu Mosaic.Monga wopanga zinyalala magalasi mphero, zinyalala magalasi mphero opangidwa ndi HCM Machinery amapereka zabwino zida thandizo yobwezeretsanso zinyalala galasi.Lero, tiyambitsa njira yopangira magalasi obwezeretsanso magalasi a Mose.

1. Phindu la thanthwe la phosphate: Kupindula kwa thanthwe la phosphate ndilo sitepe yoyamba pokonza mwala wa phosphate, womwe cholinga chake ndi kulekanitsa mchere wothandiza ndi zosafunika za m’mwala wa phosphate mwa njira zakuthupi ndi za mankhwala.Njira zodzithandizira zodziwika bwino zimaphatikizapo kulekanitsa mphamvu yokoka, kuyandama komanso kupatukana kwa maginito.Kulekanitsa mphamvu yokoka kumagwiritsa ntchito kusiyana kwa kachulukidwe ka mchere mu ore polekanitsa, kuyandama kumagwiritsa ntchito kusiyana kwa minerals mu ore kuti alekanitse, ndipo kupatukana kwa maginito kumagwiritsa ntchito kusiyana kwa maginito kwa mchere mu ore polekanitsa.

2. Kuphwanyidwa ndi kugaya miyala ya phosphate: thanthwe la phosphate pambuyo pa kupindula, liyenera kuphwanyidwa ndi kupera mankhwala, kuti atulutse bwino mchere wothandiza mu miyalayo.Kuphwanya nthawi zambiri ntchito nsagwada crusher, cone crusher ndi zipangizo zina kuthyola phosphate thanthwe mu yoyenera tinthu kukula.Kupera ndikugwiritsa ntchito makina akuluakulu opangira mphero ndi makina opangira ufa wa phosphate popera miyala yophwanyidwa, kuti ikwaniritse zofunikira za fineness.

3. Kukhetsa mwala wa phosphate: Kukhetsa ndi sitepe yofunika kwambiri pokonza mwala wa phosphate, umene zinthu zothandiza monga phosphate zimatha kusungunuka kuchokera mu miyalayo.Njira zomwe zimagwiritsidwa ntchito kwambiri ndi leaching acid, leaching alkali ndi leaching oxidation.Acid leaching imagwiritsa ntchito njira ya acidic kusungunula phosphate, leaching ya alkaline imagwiritsa ntchito njira ya alkaline kusungunula phosphate, ndipo oxidative leaching amagwiritsa ntchito oxidizing agent kusungunula phosphate.

4. Mpweya ndi kusefera kwa miyala ya phosphate: Pambuyo pobowoleza, yankho la zinthu zothandiza monga phosphate liyenera kuphikidwa ndi kusefedwa kuti lilekanitse zinthu zolimba za phosphate.Mpweya ndi kugwiritsa ntchito precipitating agent kutembenuza gawo la phosphate la yankho kukhala mvula yolimba, ndipo kusefera ndiko kulekanitsa matope kuchokera ku yankho pogwiritsa ntchito zida zosefera.

5. Kuyanika ndi kuthira mwala wa phosphate: Dothi likasefedwa, liyenera kuumitsa ndi kuthiramo kuti mutenge mankhwala a phosphate.Kuyanika ndi kugwiritsa ntchito zida zowumitsira madzi kuti zisungunuke m'nthambi, ndipo kuyanika ndiko kuyanika kwa dothi pa kutentha kwakukulu, kotero kuti kumapanga tinthu tating'ono ta phosphate.

6. Phosphate ore tailings treatment: phosphate ore processing process idzatulutsa kuchuluka kwa michira, michira imakhala ndi mchere wosatulutsidwa ndi zonyansa.Kuti muchepetse kuwonongeka kwa chilengedwe komanso kuwononga zinthu, misala iyenera kuthandizidwa.Njira zodziwika bwino zochizira ma tailings zimaphatikizira kusungitsa ma tailings, kubwezereranso ma tailings ndi kugwiritsa ntchito mokwanira.

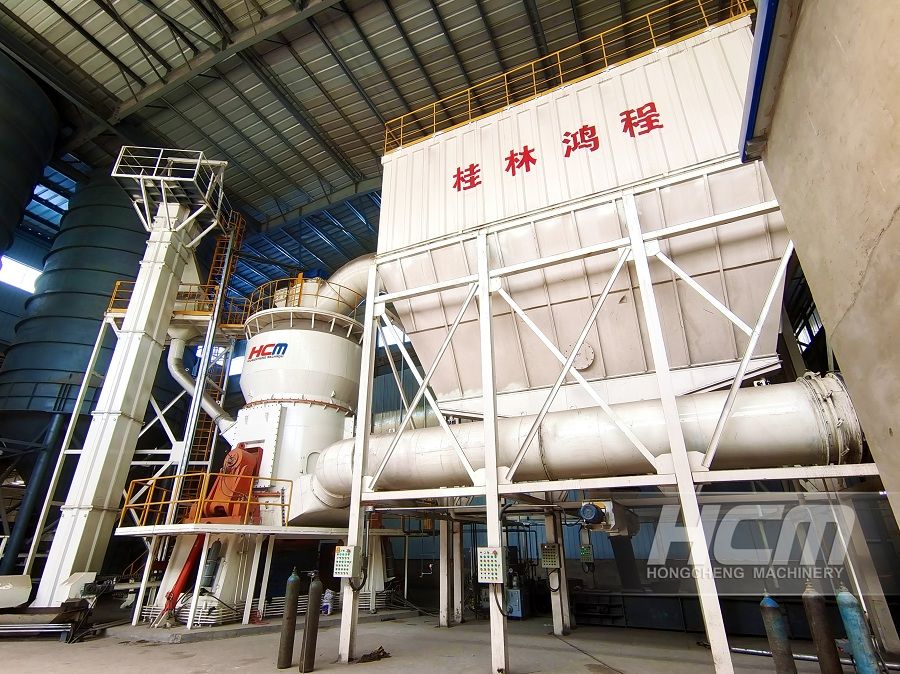

Njira yopangira magalasi obwezeretsanso magalasi a Mose: njira yosungunula ndi njira yosungunuka imagwiritsidwa ntchito, ndipo njira yopangira sintering ndi ceramic Mosaic ndizofanana.Waukulu kupanga ndondomeko ndi bwino pogaya zinyalala galasi kudzera zinyalala galasi mphero kukwaniritsa fineness amafuna galasi ufa, ndiyeno kuwonjezera kuchuluka kwa zomata wothandizila (zosakhazikika kapena organic can) ndi mitundu wothandizira kapena decolorizing wothandizira, ndi chosakanizira kusakaniza mu yunifolomu pawiri.The osakaniza mbamuikha akalumikidzidwa zosiyanasiyana geometric ndi youma kukanikiza njira, ndi zouma thupi anatumiza kwa wodzigudubuza ng'anjo, kukankha mbale mbale ndi ng'anjo ndi kutentha kwa 800-900 madigiri Celsius kwa sintering.Nthawi zambiri, imakhala m'malo otentha kwa maola 1.5-2.5.Zozizira zotuluka mu uvuni kuti ziwonedwe, kuyika, kuyanika, kuyang'ana, kuyika, kusungirako kapena fakitale, zinthu zosayenerera zimasinthidwanso.The kusungunuka njira zachokera zinyalala galasi (kuchuluka kwa anthu 25-60%) monga zopangira chachikulu, kuwonjezera kuchuluka kwa silika mchenga, feldspar, laimu, koloko phulusa ndi emulsion wothandizila, mitundu wothandizila mwa zinyalala galasi akupera. limagwirira mu yunifolomu yofananira ufa, ndiyeno mu ng'anjo mkulu kutentha kusungunuka (kutentha kutentha ndi 1400-1500) kusungunula mu yunifolomu galasi madzi.Madzi a galasi amalowa mu kalendala ndipo amakanikizidwa mu galasi la kukula kwake ndi mawonekedwe ake, omwe amatumizidwa ku ng'anjo yowotchera.Zogulitsa zomwe zasungidwa zimatha kusungidwa kapena kuperekedwa pambuyo poziyendera, kuziyika ndi kuziyika.

Kubwezeretsanso magalasi a zinyalala Zojambula zamagalasi zimatengera kugaya magalasi otayika kukhala ufa wagalasi.Zinyalala galasi mphero ndi zipangizo kupanga pokonza galasi ufa.Chigayo cha magalasi otayira opangidwa ndiMakina a HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nthawi yotumiza: Jan-08-2024