Ingilazi yemfucuza iwuhlobo lwemfucuza yasekhaya, ukuba khona kwayo akubangeli nje ukulimala nokuphazamiseka ekukhiqizeni nasekuphileni kwabantu, kodwa futhi iletha ukungcoliswa kwemvelo, ithatha umhlaba obalulekile, futhi yandisa umthwalo wemvelo.Kulinganiselwa ukuthi iShayina ikhiqiza cishe amathani ayizigidi ezi-3.2 ezingilazi zikadoti minyaka yonke, okwenza cishe u-2% wesamba sesamba sikamasipala sikadoti.Ngokuthuthukiswa kwamandla kazwelonke aphelele kanye nokuthuthukiswa kwezinga lokuphila kwabantu, inani eliphelele lengilazi yemfucuza liye landa.Mayelana nokugaywa kabusha kanye nokusetshenziswa kwezingilazi zikadoti, amanye amazwe athuthukile e-United Kingdom nase-United States azuze imiphumela emangalisayo.Amazwe aseYurophu naseMelika asebenzise ngempumelelo ingilazi yemfucuza emisebenzini yokwakha, okuyindlela ephumelelayo yokusebenzisa ingilazi enkulu yemfucuza.Ngoba zonke izinhlobo zengilazi yemfucuza ayidingi ukuhlungwa, asikho isidingo sombala.Isibonelo, ingilazi yemfucuza icutshungulwa njengento yokuhlobisa yokwakha ngoMose.Njengomkhiqizi wokugaya ingilazi yengilazi, umshini wokugaya ingilazi okhiqizwe i-HCM Machinery uhlinzeka ngosizo oluhle lwemishini yokugaywa kabusha kwezingilazi zemfucuza.Namuhla, sizokwethula inqubo yokukhiqiza ingilazi yengilazi egaywe kabusha kaMose.

1. Ukuhlomula kwetshe le-phosphate: Ukuhlomula kwetshe le-phosphate kuyisinyathelo sokuqala sokucutshungulwa kwetshe le-phosphate, okuhloswe ngalo ukuhlukanisa amaminerali awusizo nokungcola okusemadwaleni e-phosphate ngezindlela zenyama nezamakhemikhali.Izindlela ezijwayelekile zokuzuza zihlanganisa ukuhlukaniswa kwamandla adonsela phansi, ukuntanta kanye nokuhlukaniswa kazibuthe.Ukwehlukaniswa kwamandla adonsela phansi kusebenzisa umehluko wokuminyana wamaminerali enhlabathini ukuze kuhlukaniswe, ukuntanta kusebenzisa umehluko we-buoyancy wamaminerali enhlabathini ukuze ahlukanise, futhi ukuhlukaniswa kazibuthe kusebenzisa umehluko kazibuthe wamaminerali ensimbi ukuze kuhlukaniswe.

2. Ukuchotshozwa kanye nokugaywa kwetshe le-phosphate: idwala le-phosphate ngemva kokuzuzisa, lidinga ukuchotshozwa nokwelashwa kokugaya, ukuze kukhululwe kangcono amaminerali awusizo ensimbi.Ukuchoboza kuvame ukusetshenziswa umshini wokugaya imihlathi, i-cone crusher nezinye izinto ukuphula idwala le-phosphate libe usayizi wezinhlayiyana ezifanele.Ukugaya ukusetshenziswa komshini omkhulu wokugaya kanye nokucubungula umshini we-phosphate powder ukuze ugaye insimbi echotshoziwe, ukuze ihlangabezane nezidingo zokucwenga ezidingekayo.

3. Ukucwiliswa kwetshe le-phosphate: Ukucwiliswa kuyisinyathelo esibalulekile ekucutshungulweni kwetshe le-phosphate, lapho izithako eziwusizo ezifana ne-phosphate zingancibilika etsheni.Izindlela ezivame ukusetshenziswa ezisetshenziswayo zifaka i-acid leaching, i-alkali leaching kanye ne-oxidation leaching.Ukucwiliswa kwe-asidi kusebenzisa isisombululo esine-asidi ukuncibilikisa i-phosphate, ukucwiliswa kwe-alkaline kusebenzisa isixazululo se-alkaline ukuncibilikisa i-phosphate, kanti ukucwiliswa kwe-oxidative kusebenzisa i-oxidizing agent ukuncibilikisa i-phosphate.

4. Ukuna nokuhluzwa kwe-phosphate ore: Ngemva kokucwiliswa, isixazululo sezingxenye eziwusizo njenge-phosphate sidinga ukuncishiswa futhi sisefwe ukuze kuhlukaniswe imikhiqizo eqinile ye-phosphate.Imvula iwukusetshenziswa kwe-ejenti ethela amanzi ukuguqula ingxenye ye-phosphate yesisombululo ibe imvula eqinile, futhi ukuhlunga kuwukuhlukaniswa kwenhlabathi esixazululweni ngokuhlunga okokusebenza.

5. Ukomiswa nokucwiliswa kwetshe le-phosphate: Ngemva kokuba inzika isihlungiwe, kudingeka yomiswe futhi ifakwe emanzini ukuze kutholwe umkhiqizo osuphelile we-phosphate.Ukomisa ukusetshenziswa kwemishini yokomisa ukuze kuhwamuke amanzi enhlabathini, futhi ukucwilisa ukubola kuwukoma kwenhlabathi ekushiseni okuphezulu kwamazinga okushisa, ukuze kwakheke izinhlayiya eziminyene ze-phosphate.

6. Ukwelashwa kwe-phosphate ore tailings: inqubo yokucubungula i-phosphate ore izokhiqiza inani elithile lemisila, i-tailings iqukethe amaminerali angakhishiwe kanye nokungcola.Ukuze kuncishiswe ukungcoliswa kwemvelo kanye nokumoshwa kwezinsiza, izinsalela zidinga ukuphathwa.Izindlela ezijwayelekile zokwelapha i-tailings zihlanganisa ukupakishwa kwe-tailings, ukugaywa kabusha kwe-tailings kanye nokusetshenziswa okuphelele kwe-tailings.

Inqubo yokukhiqiza yengilazi kadoti egaya kabusha ingilazi KaMose: indlela yokucwilisa kanye nendlela yokuncibilika ngokuvamile isetshenziswa, futhi indlela yokukhiqiza yendlela ye-sintering kanye ne-ceramic Mosaic iyafana ngokuyisisekelo.Inqubo yokukhiqiza eyinhloko ukugaya kahle ingilazi yemfucuza ngokusebenzisa isigayo sengilazi kadoti ukuze kuhlangatshezwane nezidingo zokucoleka kwempushana yengilazi, bese wengeza inani elithile le-ejenti enamathelayo (i-inorganic noma i-organic can) kanye ne-ejenti yombala noma i-ejenti yokususa umbala, mixer ukuze uyixube ibe inhlanganisela efanayo.Ingxube icindezelwa emimoyeni ehlukahlukene yejiyomethri ngendlela yokucindezela okomile, bese umzimba owomile uthunyelwa kuhhavini ye-roller, ipuleti lepuleti lomlilo kanye neziko lomhubhe elinezinga lokushisa elingu-800-900 degrees Celsius ukuze lishiswe.Ngokuvamile, ihlala endaweni yokushisa ye-sintering amahora angu-1.5-2.5.Imikhiqizo yokupholisa iphuma kuhn ukuze ihlolwe, ibekwe, yomiswe, ihlolwe, ifakwe, igcinwe noma ifekthri, imikhiqizo engafanelekile igaywe kabusha.Indlela yokuncibilika isekelwe kudoti engilazi (inani labantu lingama-25-60%) njengezinto zokusetshenziswa eziyinhloko, engeza inani elithile lesihlabathi se-silica, i-feldspar, i-limestone, i-soda ash kanye ne-emulsion agent, i-ejenti yombala ngokusebenzisa ukugaya ingilazi yokugaya. indlela ibe impushana ehambisanayo, bese ifakwa kuhhavini lokushisa eliphezulu elincibilikayo (izinga lokushisa elincibilikayo lingu-1400-1500) ukuze lincibilike libe uketshezi lwengilazi olufanayo.Uketshezi lwengilazi lugeleza lungene ekhalendeni bese lucindezelwa kubhulokhi yengilazi enosayizi othize nokuma, ethunyelwa kuhho lomlilo.Imikhiqizo efakwe emanzini ingagcinwa noma ilethwe ngemva kokuhlolwa, ukubekwa kanye nokupakishwa.

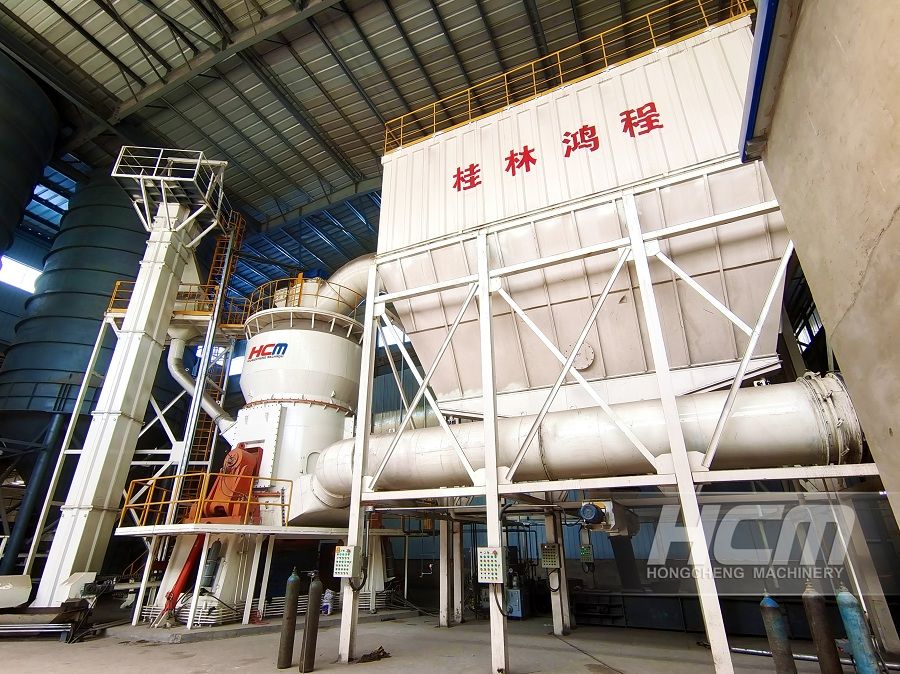

Ukugaywa kabusha kwengilazi yemfucuza Ama-mosaic engilazi asekelwe ekugayeni udoti ube yimpushana engilazi.I-Waste glass mill iyimishini yokukhiqiza yokucubungula i-glass powder.I-waste glass mill ekhiqizwa yiImishini ye-HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Isikhathi sokuthumela: Jan-08-2024