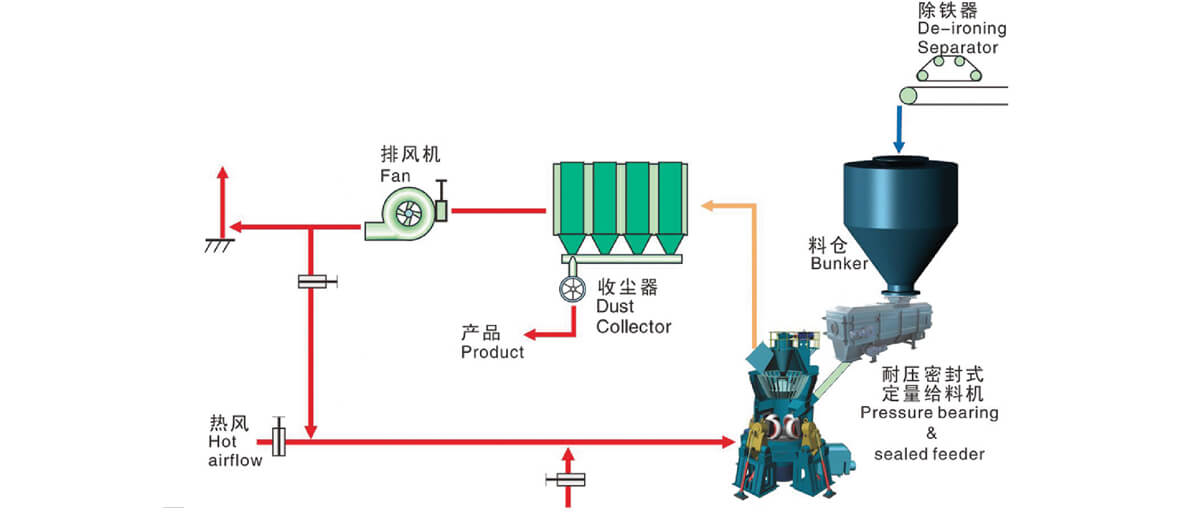

Imveliso yokugqibela inomgangatho ozinzile.Ixesha elifutshane lokuhlala lezinto eziza kwenziwa phantsi kunokuqinisekisa ukumila kwesuntswana kunye nolwelo olubalaseleyo.Iziqulatho ezimbalwa zentsimbi zilula ukususa ukuqinisekisa ubumhlophe obuphezulu kunye nokucoceka.

ukuqonda

UFUNA ISIcombululo?Ngolwazi oluthe vetshe lokusila okanye isicelo sekowuti nceda uqhagamshelane nathi.

UkubuzaQhagamshelana nathi

Wamkelekile ku Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Ifowuni:86-0773-3568321

- Idilesi:Yangtang Shanshui Industrial Park, Xicheng yoPhuhliso lwezoQoqosho Zone, Guilin City, kwiPhondo Guangxi, China

- I-imeyile:hcmkt@hcmilling.com

© Copyright - 2010-2023 : Onke Amalungelo Agciniwe.Iimveliso ezishushu - Imephu yesiza

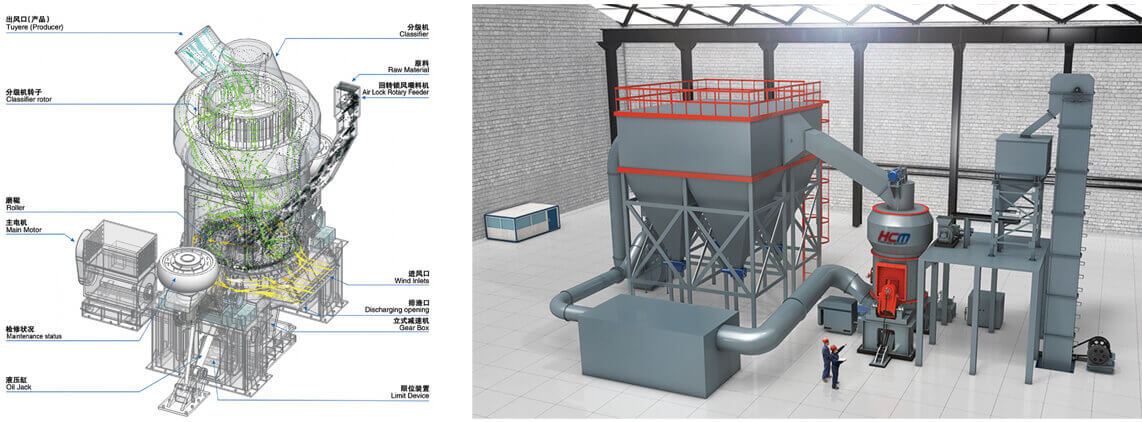

IPetroleum Coke nkqo Roller Mill, Ultra Fine Grinding Mill, UkuSila amalahle, I-Mill Grinder, Ultra Fine Mill, Ipeyinti yomgubo yokuSila iMill evela kuMboneleli waseTshayina,

IPetroleum Coke nkqo Roller Mill, Ultra Fine Grinding Mill, UkuSila amalahle, I-Mill Grinder, Ultra Fine Mill, Ipeyinti yomgubo yokuSila iMill evela kuMboneleli waseTshayina,