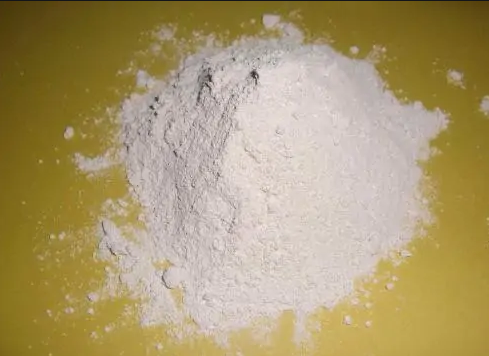

Recently, many titanium dioxide companies mentioned in their industry summary for the first half of the year that net profits increased by more than 1,000%, and titanium dioxide prices continued to rise. Many people began to call Guilin Hongcheng to ask how to deal with the waste materials from the titanium dioxide factory. Guilin Hongcheng Titanium Dioxide Waste Treatment Equipment Factory will share with you the waste treatment methods of the titanium dioxide plant below!

Titanium Dioxide Market Industry

1. What are the waste materials from titanium dioxide factory?

The waste from the titanium dioxide plant mainly contains three states: solid, gas, and liquid. This time I will mainly talk about the solid waste in the waste from the titanium dioxide plant. The waste from the titanium dioxide factory contains chemical components such as calcium, iron, and sulfur, and the main by-product is gypsum. If the waste materials from the titanium dioxide factory are directly piled or landfilled, it will cause a certain degree of damage to the environment and endanger animals, plants and humans.

2. How to deal with the waste generated by titanium dioxide factory?

There are three main ways to process waste from titanium dioxide plants:

(1) The waste material from the titanium dioxide plant contains titanium dioxide dry basis ≤ 40%, and can be treated by flotation, and then entered into the sewage treatment station for treatment.

(2) The dry basis content of the waste material in the titanium dioxide factory is less than or equal to 50% and greater than 40%. It can be independently acidolyzed, ground and further processed to produce lower-grade products.

(3) The dry basis of the waste from the titanium dioxide plant is greater than 50%. Mineral powder can be added and reground to make white gypsum for cement production. Yellow gypsum can also be produced after drying and used partially as auxiliary materials for brick-making projects and cement production. part.

(4) The waste materials from the titanium dioxide factory are processed through selection, primary crushing, grinding and other processes to produce thin-walled bricks with greatly improved strength and stability. They are light in weight, high in strength, high in safety, and have good sound and heat insulation effects.

3. What equipment is used for waste treatment in titanium dioxide plants?

The waste from the titanium dioxide factory is a type of solid waste. Guilin Hongcheng vertical mill has been used to treat solid waste for nearly 20 years. Guilin Hongcheng vertical mill equipment is a machine that integrates crushing, drying, grinding, It is an advanced grinding equipment with high efficiency and energy saving that integrates grading and conveying. The dried waste material from the titanium dioxide factory can be dry ground to 80-2500 mesh for application in downstream industries. Guilin Hongcheng has been a mining equipment R&D and manufacturer for 30 years. The company mainly sells Raymond mills, vertical mills, ultra-fine vertical mills, ring roller mills and other ore grinding equipment. Over the past 30 years, it has always adhered to its original intention. , serve every customer with integrity. To inquire about the waste treatment process of the titanium dioxide factory and the quotation of the grinding mill, please contact us. Mail:hcmkt@hcmilling.com

Post time: Sep-22-2023