Slag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators. What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:

Now people often say that the slag mainly refers to the waste slag discharged from the blast furnace after ironmaking, that is, the blast furnace slag. Usually, the slag in the high temperature melting state is rapidly cooled by water quenching to become water slag. Water slag is an important material for the production of mineral powder, and is also a relatively ideal cementing material at present, with ideal activity and stability. Grind the water-cooled slag with slag vertical roller mill equipment to obtain ultra-fine mineral powder, which can be used to produce non clinker or less clinker cement, or directly replace cement and add it to concrete. The advantage of this is that it can consume a large amount of solid wastes, realize the resource utilization of solid wastes, save natural ores, and reduce carbon dioxide emissions. It has far-reaching economic and social benefits.

What is the process flow of slag grinding treatment? There are several kinds of equipment for slag grinding treatment. At present, the equipment with environmental protection and economic benefits belongs to vertical slag grinding machine. Compared with other equipment, the slag vertical roller mill has obvious advantages in energy consumption, which can save more than 40% of power consumption, and has low noise, low maintenance cost, good shape and stable quality of finished mineral powder. Therefore, it has become an ideal slag grinding mill equipment choice for slag powder.

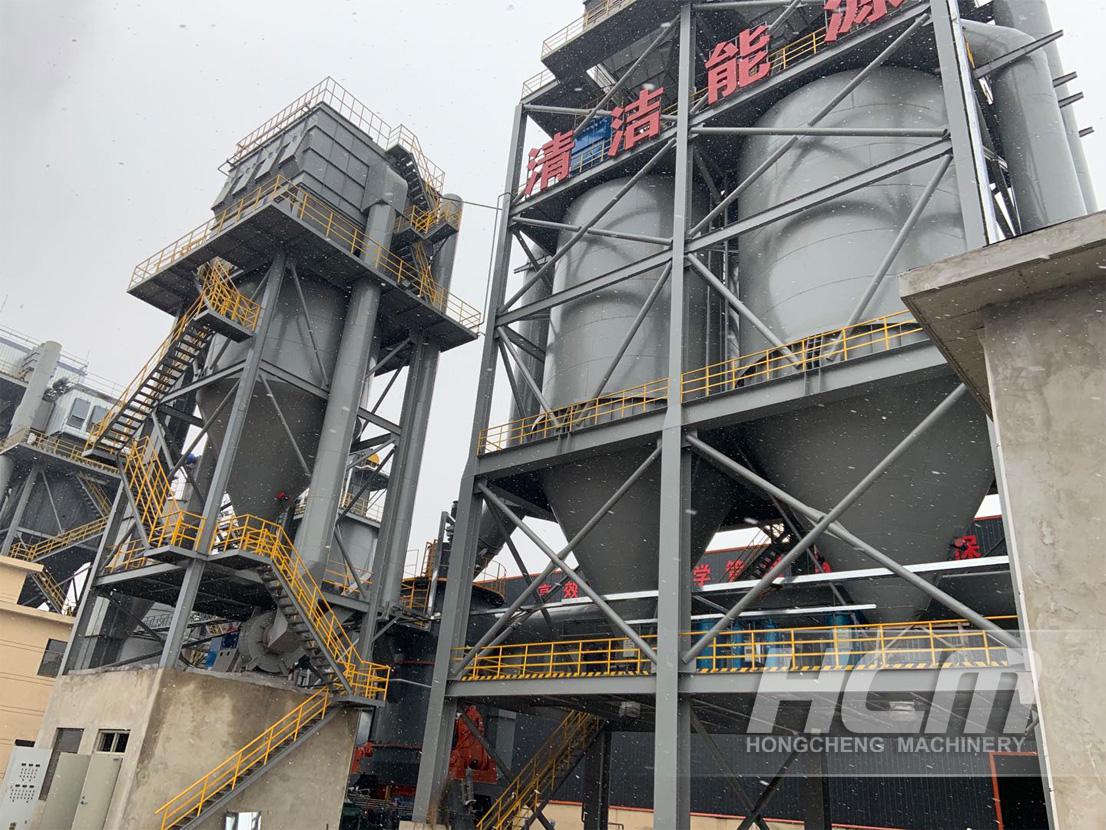

HLM series slag vertical roller mill produced by HCMilling(Guilin Hongcheng) can be widely used in slag grinding treatment. The whole set of slag grinding treatment process includes crushing, drying, grinding, grading, transportation, collection, storage and other steps, which can realize the complete production and processing of slag from large particles to finished fine powder. The slag vertical roller mill of HCMilling(Guilin Hongcheng) has stable performance, reliable quality, low noise, low dust, energy saving and high efficiency. We welcome all slag grinding mill manufacturers to come for detailed consultation.

If you have the equipment purchase demand for Slag Grinding Mill Machine, please contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check

Slag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators. What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:

Now people often say that the slag mainly refers to the waste slag discharged from the blast furnace after ironmaking, that is, the blast furnace slag. Usually, the slag in the high temperature melting state is rapidly cooled by water quenching to become water slag. Water slag is an important material for the production of mineral powder, and is also a relatively ideal cementing material at present, with ideal activity and stability. Grind the water-cooled slag with slag vertical roller mill equipment to obtain ultra-fine mineral powder, which can be used to produce non clinker or less clinker cement, or directly replace cement and add it to concrete. The advantage of this is that it can consume a large amount of solid wastes, realize the resource utilization of solid wastes, save natural ores, and reduce carbon dioxide emissions. It has far-reaching economic and social benefits.

What is the process flow of slag grinding treatment? There are several kinds of equipment for slag grinding treatment. At present, the equipment with environmental protection and economic benefits belongs to vertical slag grinding machine. Compared with other equipment, the slag vertical roller mill has obvious advantages in energy consumption, which can save more than 40% of power consumption, and has low noise, low maintenance cost, good shape and stable quality of finished mineral powder. Therefore, it has become an ideal slag grinding mill equipment choice for slag powder.

HLM series slag vertical roller mill produced by HCMilling(Guilin Hongcheng) can be widely used in slag grinding treatment. The whole set of slag grinding treatment process includes crushing, drying, grinding, grading, transportation, collection, storage and other steps, which can realize the complete production and processing of slag from large particles to finished fine powder. The slag vertical roller mill of HCMilling(Guilin Hongcheng) has stable performance, reliable quality, low noise, low dust, energy saving and high efficiency. We welcome all slag grinding mill manufacturers to come for detailed consultation.

If you have the equipment purchase demand for Slag Grinding Mill Machine, please contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.

.

Post time: Jan-04-2023