Introduction

The main component of gypsum is calcium sulfate. Generally speaking, gypsum can generally refer to raw gypsum and anhydrite. Gypsum is gypsum stone contained in nature, mainly dihydrate gypsum and anhydrite. Gypsum resources in China mainly include ordinary gypsum and anhydrite. Anhydrite accounts for more than 60% of the total, and the first-class gypsum as an excellent resource accounts for only 8% of the total. Fiber gypsum accounts for only 1.8% of the total. Gypsum is a widely used industrial and building material. It can be used for cement retarder, gypsum building products, model making, food additives, sulfuric acid production, paper filler, paint filler, etc.

Application area

Gypsum has rich application value and is very popular in many fields such as construction, building materials, power plant desulfurization, food, medicine and so on. The application of gypsum in China is mainly reflected in the following aspects: 84% is used as retarder for cement production, 6.5% for ceramic molds, 4.0% for gypsum products and wall materials, and 5.5% for chemical and other industries. With the in-depth application of gypsum grinding equipment, the application value of gypsum powder continues to expand. Among them, the application value of building gypsum production line and desulfurization gypsum production line.

1. Building gypsum: gypsum is very popular in the field of building materials. The building gypsum products manufactured by gypsum grinding equipment have good fire resistance and are deeply loved by building engineering. The gypsum production line produced by Hongcheng meets the requirements of energy conservation and emission reduction and covers a number of patented technologies. The effectively produced powder is a wise choice for gypsum powder customers.

2. Power plant desulfurization gypsum: desulfurization gypsum is a by-product of limestone power plant desulfurization process widely used, and its processing and utilization value is very high. It adopts a professional desulfurization gypsum production line, which can improve the application value of desulfurization gypsum as a by-product. Among them, limestone gypsum wet desulfurization process is technically mature and widely used. Only limestone wet desulfurization gypsum is convenient for application. Desulfurized gypsum has very superior performance and is a good raw material for construction industry. It is relatively mature in application at home and abroad.

Industrial design

Guilin Hongcheng has a selection scheme and service team with superb technology, rich experience and enthusiastic service. Over the years of development, Hongcheng has always regarded creating value for customers as the core value, thinking about what customers think and anxious about what customers are anxious about, and taking customer satisfaction as the source power of Hongcheng's development. We have a complete set of perfect sales service system, which can provide customers with perfect pre-sales, in-sales and after-sales services. Hongcheng will assign engineers to the customer's site to do preliminary work such as planning, site selection and process scheme design, and design special production processes and processes according to the needs of different customers to meet different production needs.

Equipment Selection

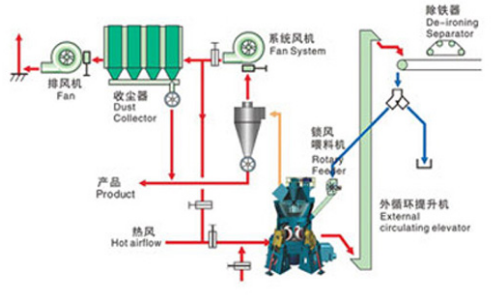

HC large pendulum grinding mill

Fineness: 38-180 μm

Output: 3-90 t/h

Advantages and features: it has stable and reliable operation, patented technology, large processing capacity, high classification efficiency, long service life of wear-resistant parts, simple maintenance and high dust collection efficiency. The technical level is at the forefront of China. It is a large-scale processing equipment to meet the expanding industrialization and large-scale production and improve the overall efficiency in terms of production capacity and energy consumption.

HCH ultrafine ring roller mill

Fineness: 5-45 μm

Output: 1-22 t/h

Advantages and features: it integrates rolling, grinding and impact. It has the advantages of small floor area, strong completeness, wide use, simple operation, convenient maintenance, stable performance, high cost performance, low investment cost, economic benefits and fast income. It is the mainstream equipment for the processing of heavy calcium ultrafine powder.

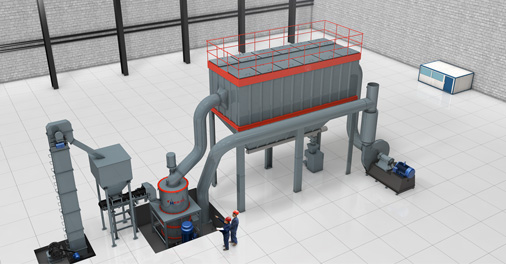

HLM vertical roller mill:

Fineness: 200-325 mesh

Output: 5-200T / h

Advantages and features: it integrates drying, grinding, grading and transportation. High grinding efficiency, low power consumption, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise, small dust and less consumption of wear-resistant materials. It is an ideal equipment for large-scale pulverization of limestone and gypsum.

Technical parameters of gypsum pulverizing main machine

|

Product specification |

Coarse powder processing (100 mesh - 400 mesh) |

Fine powder deep processing(600mesh-2000mesh) |

|

Equipment selection scheme |

Vertical mill or Raymond Mill |

Ring roller mill or ultra-fine vertical mill |

Service support

Training guidance

Guilin Hongcheng has a highly skilled, well-trained after-sales team with a strong sense of after-sales service. After sales can provide free equipment foundation production guidance, after-sales installation and commissioning guidance, and maintenance training services. We have set up offices and service centers in more than 20 provinces and regions in China to respond to customer needs 24 hours a day, pay return visits and maintain the equipment from time to time, and create greater value for customers wholeheartedly.

After-sale service

Considerate, thoughtful and satisfactory after-sales service has been the business philosophy of Guilin Hongcheng for a long time. Guilin Hongcheng has been engaged in the development of grinding mill for decades. We not only pursue excellence in product quality and keep pace with the times, but also invest a lot of resources in after-sales service to shape a highly skilled after-sales team. Increase efforts in installation, commissioning, maintenance and other links, meet customer needs all day, ensure the normal operation of equipment, solve problems for customers and create good results!

Project acceptance

Guilin Hongcheng has passed ISO 9001:2015 international quality management system certification. Organize relevant activities in strict accordance with the certification requirements, conduct regular internal audit, and continuously improve the implementation of enterprise quality management. Hongcheng has advanced testing equipment in the industry. From casting raw materials to liquid steel composition, heat treatment, material mechanical properties, metallography, processing and assembly and other related processes, Hongcheng is equipped with advanced testing instruments, which effectively ensures the quality of products. Hongcheng has a perfect quality management system. All ex factory equipment are provided with independent files, involving processing, assembly, testing, installation and commissioning, maintenance, parts replacement and other information, creating strong conditions for product traceability, feedback improvement and more accurate customer service.

Post time: Oct-22-2021