Introduction to petroleum coke

Petroleum coke is distillation to separate the light and heavy oils, heavy oil turn into end product by thermal cracking process. Tell from the appearance, coke is irregular in shape and sizes of black lumps (or particles) a metallic luster; coke particles having porous structure, the main elements is carbon, possession of more than 80wt%, the rest is hydrogen, oxygen, nitrogen, sulfur and metal elements. Chemical properties of petroleum coke with its unique physical and chemical properties and mechanical properties. The non-volatile carbon which is heat part of itself, volatile matter and mineral impurities (sulfur, metal compounds, water, ash, etc.), all those indicators determines coke’s chemical properties.

Needle coke: have obvious needle structure and fiber texture, majority applied as high power graphite electrode in steel-making. For needle coke has strict quality requirement in sulfur content, ash content, volatile and true density etc, so that there are special requirement for needle coke’s processing art and raw material.

Sponge coke: high chemical reactivity, low impurity content, mainly used in aluminum industry and carbon industry.

Shot coke or globular coke: cylindrical spherical shape, the diameter of 0.6-30mm, usually produced by a high-sulfur, high asphalting residue, it can only be used for power generation, cement and other industrial fuel.

Powder coke: produced through fluidized coking processing, particles are fine (diameter of 0.1-0.4mm), high volatile and thermal expansion coefficient makes it cannot be directly used in electrodes and carbon industry.

Application of Petroleum coke

The main application field of petroleum coke in China is electrolytic aluminum industry, accounting for more than 65% of the total consumption of petroleum coke. Followed by carbon, industrial silicon and other smelting industries. Petroleum coke is mainly used as fuel in cement, power generation, glass and other industries, accounting for a small proportion. At present, the supply and demand of domestic petroleum coke is basically the same. However, due to the export of a large number of low sulfur high-end petroleum coke, the total supply of domestic petroleum coke is insufficient, and medium and high sulfur petroleum coke needs to be imported for supplement. With the construction of a large number of coking units in recent years, the output of domestic petroleum coke will be improved and expanded.

①Glass industry is a high energy consumption industry. Its fuel cost accounts for about 35% ~ 50% of the glass cost. Glass furnace is an equipment with more energy consumption in glass production line. ② Once the glass furnace is ignited, it cannot be shut down until the furnace is overhauled (3-5 years). Therefore, fuel must be continuously added to ensure the furnace temperature of thousands of degrees in the furnace. Therefore, the general pulverizing workshop will have standby mills to ensure continuous production. ③ Petroleum coke powder is used in the glass industry, and the fineness is required to be 200 mesh D90. ④ The water content of raw coke is generally 8% - 15%, and it needs to be dried before entering the mill. ⑤ The lower the moisture content of the finished product, the better. Generally, the dehydration effect of the open circuit system is better.

Process flow of petroleum coke pulverization

Key parameter of petroleum coke grinding

|

Grindability factor |

Primary moisture(%) |

End moisture(%) |

|

>100 |

≤6 |

≤3 |

|

>90 |

≤6 |

≤3 |

|

>80 |

≤6 |

≤3 |

|

>70 |

≤6 |

≤3 |

|

>60 |

≤6 |

≤3 |

|

<40 |

≤6 |

≤3 |

Remarks:

1. The grindable coefficient parameter of petroleum coke material is the factor affecting the output of grinding mill. The lower the grindable coefficient, the lower the output;

- The initial moisture of raw materials is generally 6%. If the moisture content of raw materials is greater than 6%, the dryer or mill can be designed with hot air to reduce the moisture content, so as to improve the output and quality of finished products.

Petroleum coke powder making machine model selection program

| 200mesh D90 | Raymond mill |

|

| Vertical Roller Mill | 1250 Vertical Roller Mill is using in Xiangfan, it is high energy consumption because of its old type and without updating for years. What customer cares is the function of get through hot air. | |

| Impact mill | Market share of 80% in Mianyang, Sichuan and Suowei, Shanghai before 2009, it is eliminating now. |

Analysis of advantages and disadvantages of various grinding mills:

Raymond Mill: with low investment cost, high output, low energy consumption, stable equipment and low maintenance cost, it is an ideal equipment for petroleum coke pulverization;

Vertical mill: high investment cost, high output and high energy consumption;

Impact mill: low investment cost, low output, high energy consumption, high equipment failure rate and high maintenance cost;

Analysis on grinding mill models

Advantages of HC series grinding mill in petroleum coke pulverizing:

1. HC Petroleum Coke mill structure: high grinding pressure and high output, which is 30% higher than that of ordinary pendulum mill. The output is more than 200% higher than that of impact mill.

2. High classification accuracy: the product fineness generally requires 200 mesh (D90), and if it is higher, it will reach 200 mesh (D99).

3. The grinding mill system has low noise, low vibration and high environmental protection performance.

4. Low maintenance rate, convenient maintenance and low labor cost.

5. According to the process requirements, the mill system can pass 300 ° C hot air to realize the production of drying and grinding (the case of Three Gorges building materials).

Remarks: at present, HC1300 and HC1700 grinding mill have a market share of more than 90% in the field of petroleum coke pulverization.

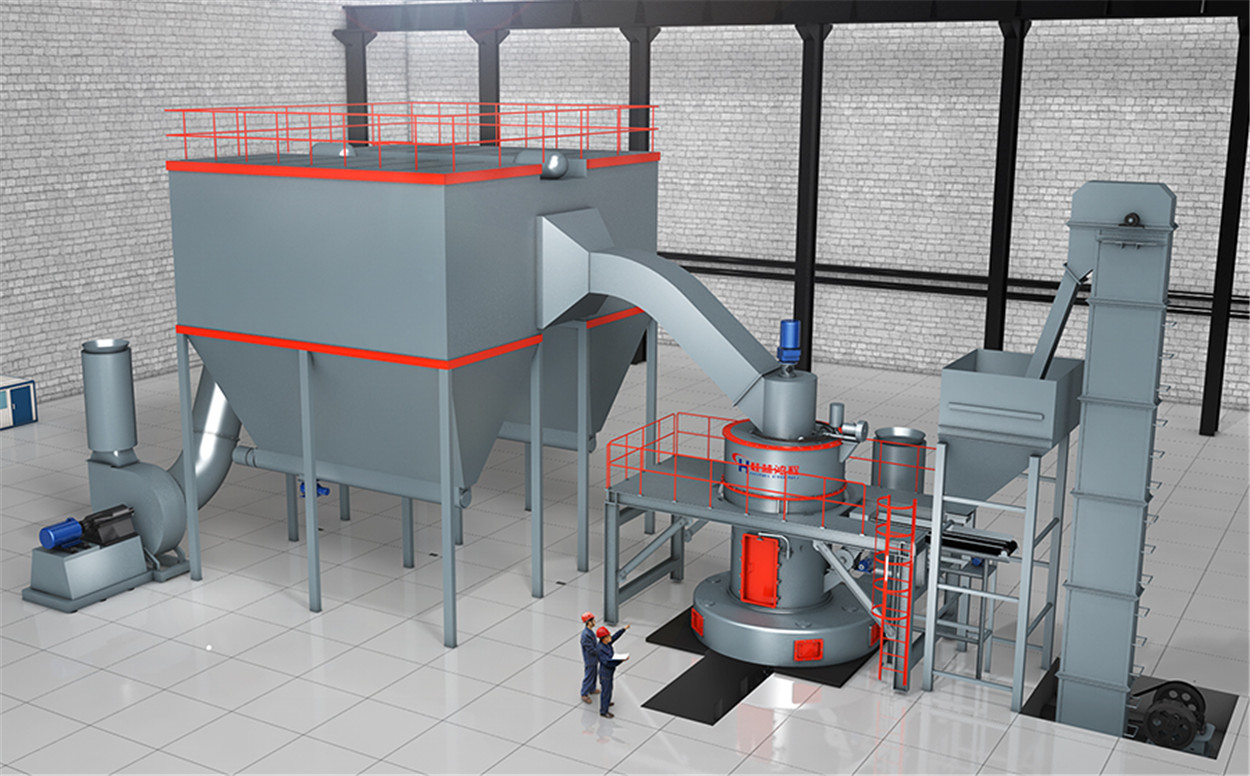

Stage I: Crushing of raw materials

The large petroleum coke material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill.

Stage II: Grinding

The crushed petroleum coke small materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage III: Classifying

The milled materials are graded by the grading system, and the unqualified powder is graded by the classifier and returned to the main machine for re grinding.

Stage V: Collection of finished products

The powder conforming to the fineness flows through the pipeline with the gas and enters the dust collector for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then packaged by the powder tanker or automatic packer.

Application examples of petroleum coke powder processing

Model and number of this equipment: 3 HC2000 production lines

Processing raw materials: pellet coke and sponge coke

Fineness of finished product: 200 mesh D95

Capacity: 14-20t / h

The owner of the project has inspected the equipment selection of petroleum coke grinding mill for many times. Through comprehensive comparison with many milling machine manufacturers, they have successively purchased many sets of Guilin Hongcheng HC1700 milling machine and HC2000 milling machine equipment, and have been friendly and cooperative with Guilin Hongcheng for many years. In recent years, many new glass production lines have been built. Guilin Hongcheng has sent engineers to the customer's site for many times according to the needs of the owner. Guilin Hongcheng grinding mill equipment has been used in the petroleum coke pulverizing projects of the glass factory in recent three years. The petroleum coke pulverizing production line designed by Guilin Hongcheng has stable operation, high output, low energy consumption and less dust pollution in the pulverizing workshop, which has been highly praised by customers.

Post time: Oct-22-2021