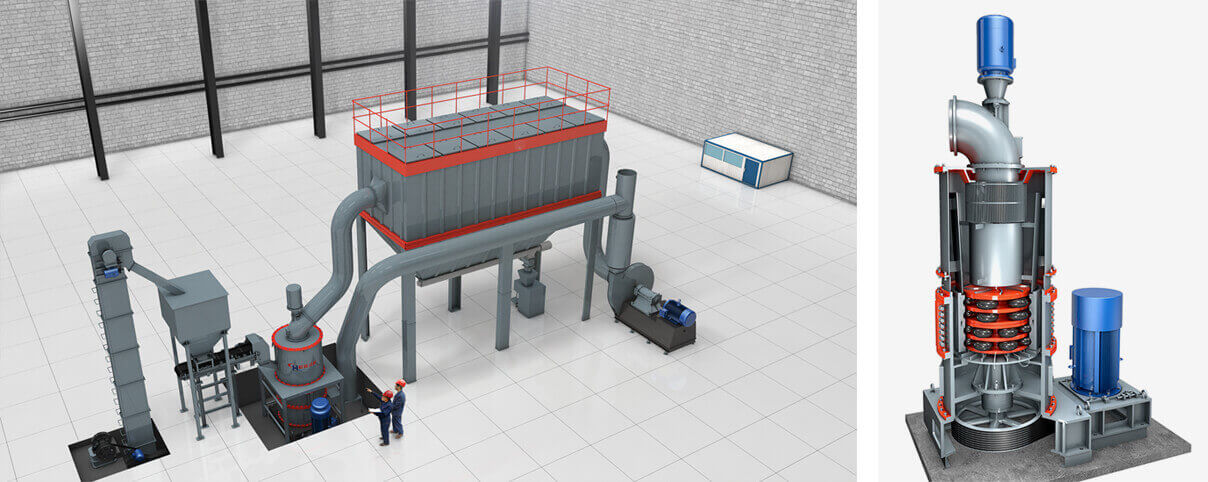

Umyinge ophezulu wokutyumza. Ubungakanani botyando olwenziweyo obungaphantsi kwe-10mm bunokonwatyiswa ukuba bube mhle<I-10μm (97% edlula). Kwaye ukulunga kokugqibela ngaphantsi kwe-3um ibalwa malunga ne-40%, enegalelo kwindawo enkulu yomphezulu.

qonda

Ufuna isisombululo?Ngolwazi oluninzi lwe-Guill Guily okanye isicelo sekowuti nceda uqhagamshelane nathi.

UmbuzoQhagamshelana nathi

Wamkelekile kwi-HongchengI-Ginein Hongcheng Izixhobo zeMveliso yeMveliso ye-CO YTD.

- Ifowuni:I-86-16107733434

- Idilesi:I-Yangtang Shanshui Commoriver Park, I-Xicheng yoPhuculo lwezoQoqololo, iSixeko seGuangan, iPhondo laseGuangan, China

- I-imeyile:hcmkt@hcmilling.com

© Copyright-2010-2525: Onke amalungelo agciniwe.Iimveliso ezishushu - Indawo

Gallimitha, I-Petroleum Coke rill roner mill, I-Ultra i-Guind Greeting Gloing, I-Ultra i-Guily Milling, I-Coal grind, I-powder paind grinding greing ukusuka kwi-China ubugosa,

Gallimitha, I-Petroleum Coke rill roner mill, I-Ultra i-Guind Greeting Gloing, I-Ultra i-Guily Milling, I-Coal grind, I-powder paind grinding greing ukusuka kwi-China ubugosa,