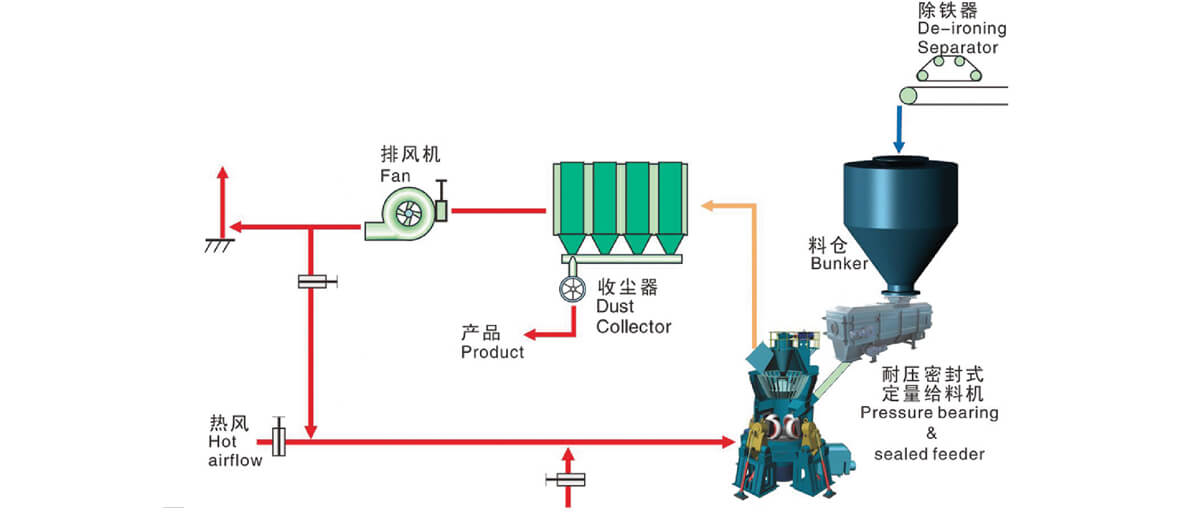

Shayga ugu dambeeya wuxuu leeyahay tayo xasilloon. Waqtiga Gundhig Gundhig Gundhig ee maaddada dhulka ayaa xaqiijin kara xitaa qaabka walxaha walxaha iyo dareeraha wanaagsan. In yar oo bir ah oo bir ah way fududahay in laga saaro dammaanad si aad u dammaanad qaadaan cadaanka sare iyo daahirnimo.

fahmid

Ma u baahan tahay xalka?Si aad u hesho macluumaad Mill Mill ah oo Dheeraad ah ama Codsi Qowlcid Fadlan nala soo xiriir.

Su'aalo weydiintanala soo xiriir

Ku soo dhawow Guilin HongchengenSoosaarka qalabka macdanta Guilin Hongcheng Co., Ltd.

- Telefoon:86-1510773444

- Cinwaanka:Yangbang Shanshui Park, aag horumarinta dhaqaalaha ee Xicheng, Guilin City, gobolka Guangxi, Shiinaha

- E-mayl:hcmkt@hcmilling.com

Xuquuqda daabacaadda - 2010-2025: Dhammaan xuquuqda ayaa la ilaaliyay.Alaabada kulul - Hartemap

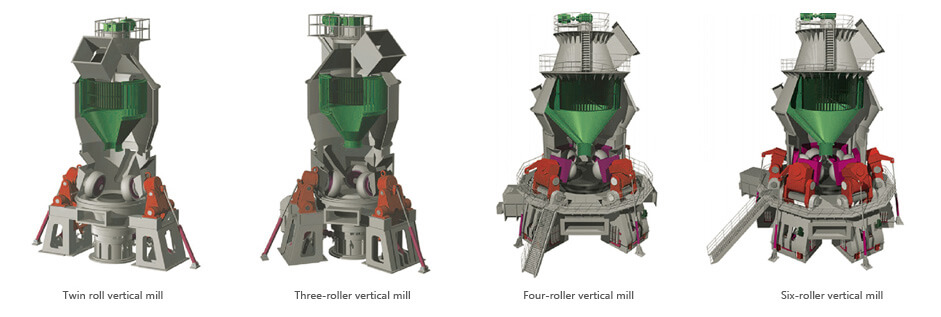

Powder rinji rinji mashiinka china oo ka soo baxay alaab-qeybiyeyaasha Shiinaha, Batroolka cokelum coke vertical roller, Dhuxul dhuxul, Ultra ganaax ganaax ah, Mill Boorta, Ultra ganaax ganaax ah,

Powder rinji rinji mashiinka china oo ka soo baxay alaab-qeybiyeyaasha Shiinaha, Batroolka cokelum coke vertical roller, Dhuxul dhuxul, Ultra ganaax ganaax ah, Mill Boorta, Ultra ganaax ganaax ah,