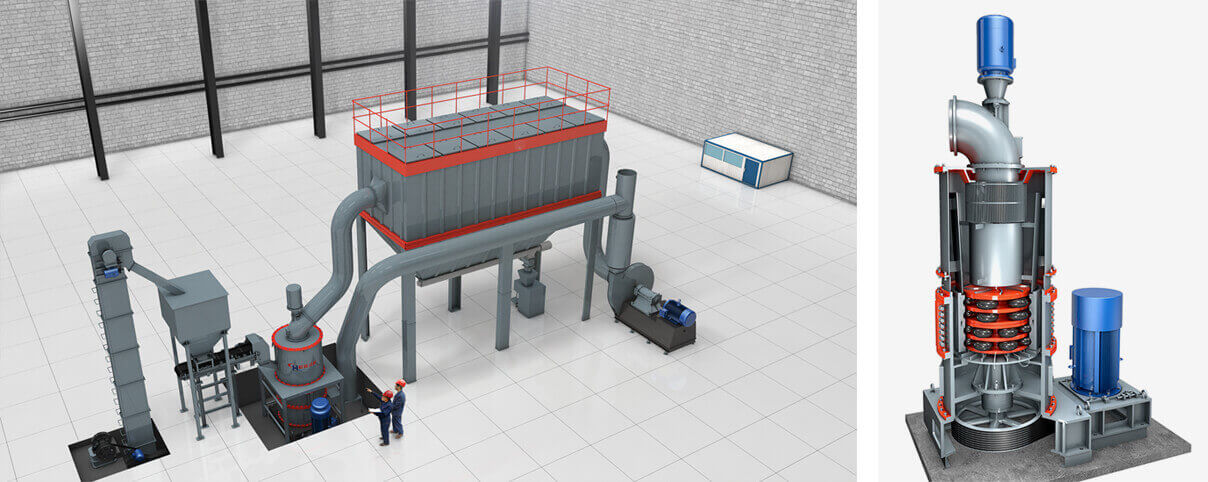

Saamiga burburka sare. Cabbirka Qeybaha Quudinta ee ka yar 10mm ayaa laga baaraandegi karaa finnish<10μm (97% gudbinta). Iyo liness-ka ugu dambeeya wax ka yar 3um ayaa la xisaabtamay qiyaastii 40%, taas oo gacan ka geysata dhul weyn oo gaar ah oo gaar ah.

fahmid

Ma u baahan tahay xalka?Si aad u hesho macluumaad Mill Mill ah oo Dheeraad ah ama Codsi Qowlcid Fadlan nala soo xiriir.

Su'aalo weydiintanala soo xiriir

Ku soo dhawow Guilin HongchengenSoosaarka qalabka macdanta Guilin Hongcheng Co., Ltd.

- Telefoon:86-1510773444

- Cinwaanka:Yangbang Shanshui Park, aag horumarinta dhaqaalaha ee Xicheng, Guilin City, gobolka Guangxi, Shiinaha

- E-mayl:hcmkt@hcmilling.com

Xuquuqda daabacaadda - 2010-2025: Dhammaan xuquuqda ayaa la ilaaliyay.Alaabada kulul - Hartemap

Mill Boorta, Batroolka cokelum coke vertical roller, Ultra ganaax ganaax ah, Ultra ganaax ganaax ah, Dhuxul dhuxul, Powder rinji rinji mashiinka china oo ka soo baxay alaab-qeybiyeyaasha Shiinaha,

Mill Boorta, Batroolka cokelum coke vertical roller, Ultra ganaax ganaax ah, Ultra ganaax ganaax ah, Dhuxul dhuxul, Powder rinji rinji mashiinka china oo ka soo baxay alaab-qeybiyeyaasha Shiinaha,