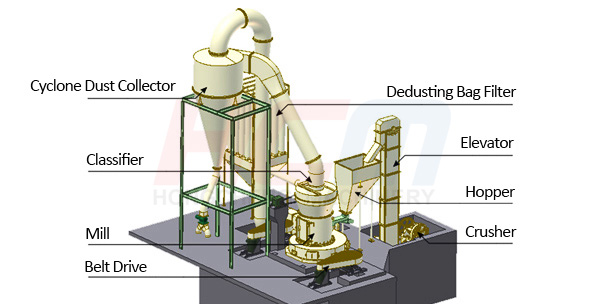

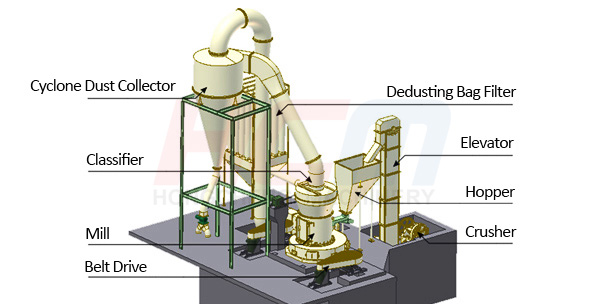

R-series roller mill is mainly composed of main mill, analysis machine, blower, bucket elevator, jaw crusher, electromagnetic vibrating feeder, electric control motor, finished cyclone separator and pipeline equipment, etc.

As the mill works, centrifugal force drives the rolls against the inner vertical surface of the grinding ring. Plows rotating with the assembly lift ground material from the mill bottom and direct it between the rolls and the grinding ring where it is pulverized. Air enters from below the grind ring and flows upward carrying fines to the classifying section. The classifier allows the sized material to pass to the product collector and returns unqualified oversized particles to the grinding chamber for further processing. The mill operates under negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the service life of major mechanical components.

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Quality Inspection for Raymond Mills Downtime - R-Series Roller Mill – HCM, The product will supply to all over the world, such as: Mongolia, luzern, Mexico, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.