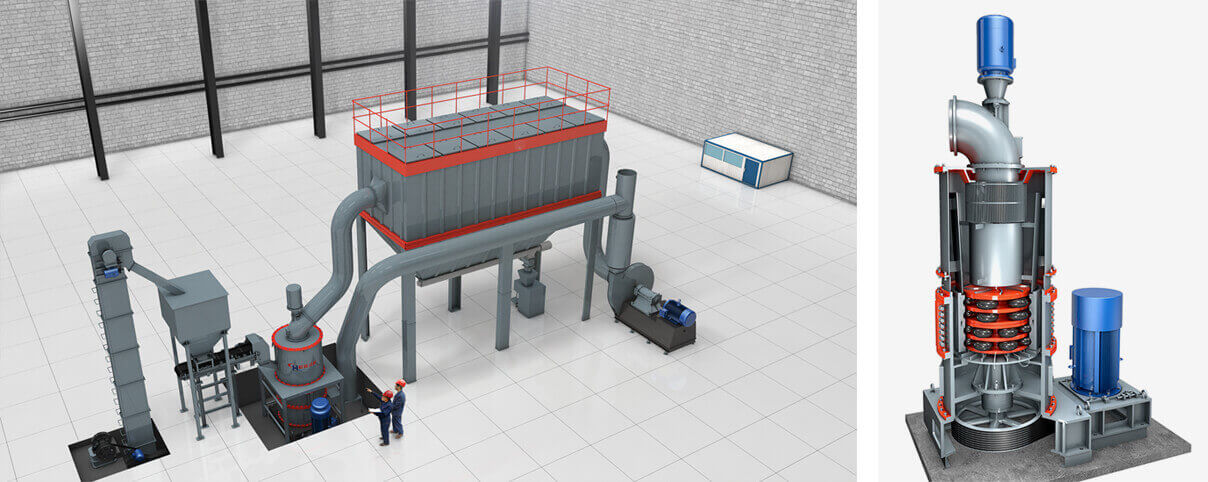

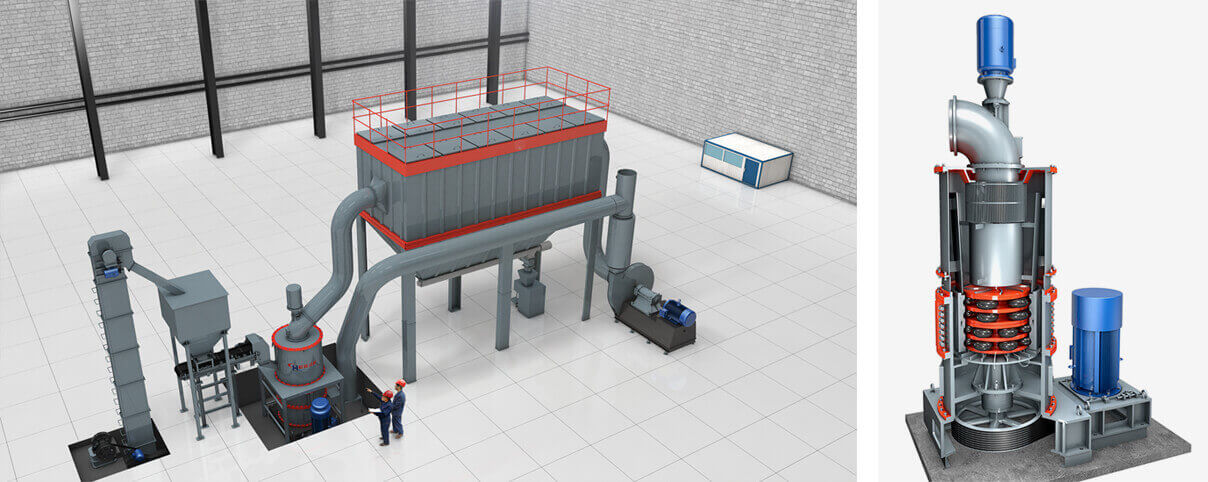

HCH ultra-fine grinding mill consists of main mill, classifier, high pressure fan, cyclone collector, pipes, electromagnetic vibrating feeder, electrical distribution cabinet and etc.

The large pieces of materials are crushed into small particles by the crusher and then sent to the storage bin by the elevator, and then sent to the tray on the turntable through the vibrating feeder and the inclined feeding pipe. The material is scattered to the periphery of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring, and then impacted, rolled, and ground by the ring roller, the powders become ultra-fine powder after three-layer ring processing. The high-pressure blower removes the external air through suction and bring the crushed material into the powder concentrator. The rotating impeller in the powder classifier makes the coarse materials fall back and be re-ground. The qualified fine powders enters the cyclone powder collector with the airflow and are discharged from the discharge valve at the lower part of the cyclone as the finished product.

Product detail pictures:

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for OEM manufacturer Bentonite Roller Mill - HCH Ultra-Fine Grinding Mill – HCM, The product will supply to all over the world, such as: South Korea, Lahore, Jordan, Our company is an international supplier on this kind of merchandise. We supply an amazing selection of high-quality merchandise. Our goal is to delight you with our distinctive collection of mindful items while providing value and excellent service. Our mission is simple: To supply the best items and service to our customers at the lowest prices possible.