Cov khoom siv thiab txhim khu kev qha tseem ceeb ntawm cov qauv hluav taws xob muaj zog tsis kam thiab tuaj yeem txhim kho qhov ruaj khov thiab kev ntseeg tau thaum lub sijhawm ua haujlwm.

to taub yooj yim

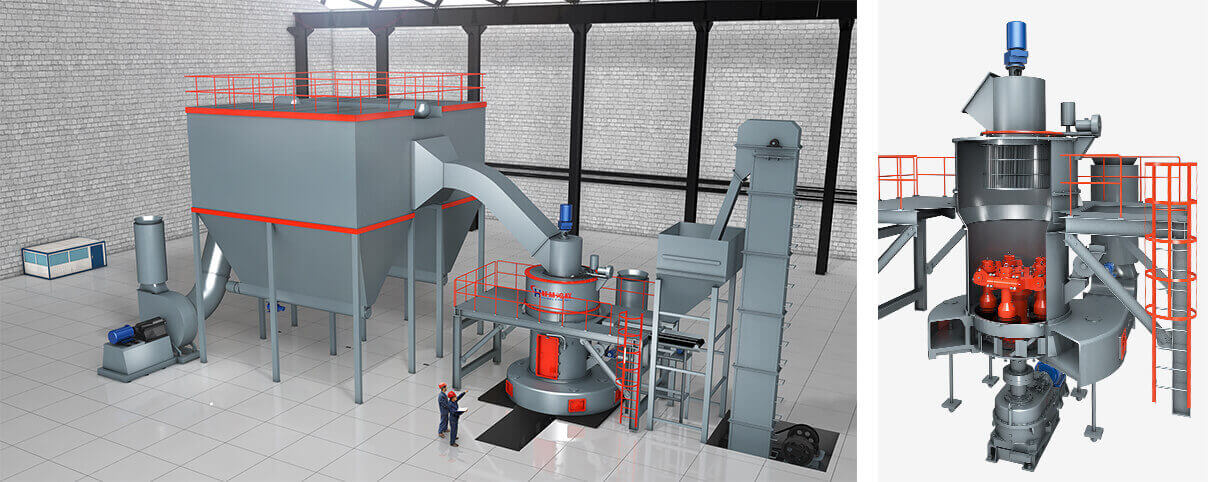

Xav tau kev daws teeb meem?Yog xav tau ntau txoj kev sib tsoo cov ntaub ntawv zeb zeb los yog hais cov lus thov thov hu rau peb.

Kev noogTiv Tauj Peb

Txais tos rau Guilin HongchengGuilin Hongcheng Mining Khoom Siv Ua Khoom Co., Ltd.

- Xov Tooj:86-15107733434

- Chaw Nyob:Yangtang Shatshui Industrial Park, Xicheng Cov Chaw Tsim Kho Kev Lag Luam, Guilin City, Guangxi Xeev, Suav

- E-mail:hcmkt@hcmilling.com

© Copyright - 2010-2025: Qoob loo.Cov Khoom Kub Kub - Kws txav chaw Sitemap

Hmoov xim sib tsoo zeb los ntawm Tuam Tshoj tsum, Ultra Nplua Sib Tsoo Zeb, Court Tsoo, Ultra nplua zeb, Zeb li, Roj Hlawv Coke Ntsug Cov Menyuam Zeb,

Hmoov xim sib tsoo zeb los ntawm Tuam Tshoj tsum, Ultra Nplua Sib Tsoo Zeb, Court Tsoo, Ultra nplua zeb, Zeb li, Roj Hlawv Coke Ntsug Cov Menyuam Zeb,