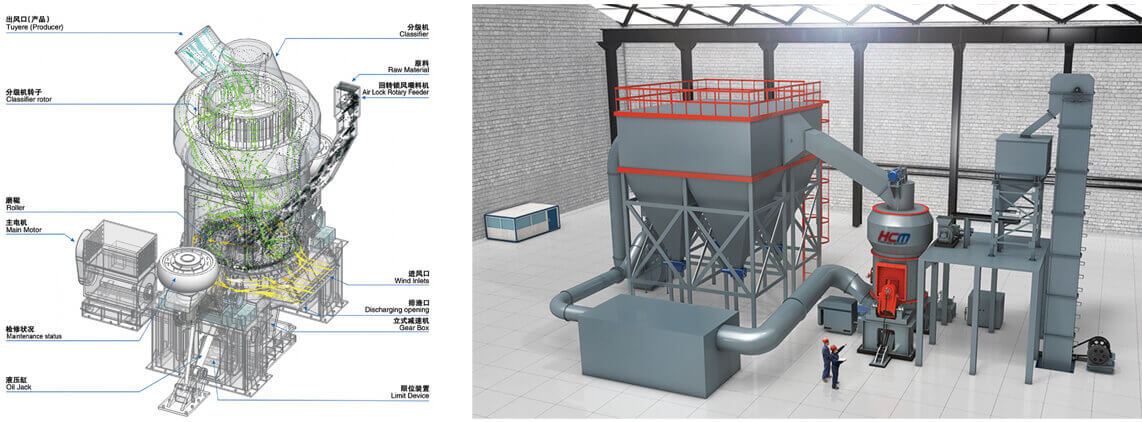

Structure and Principle

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Fast delivery China Ball Mill Mining Machine Cement Limestone Quartz Feldspar Powder Gold Copper Ore Mill, On account of superior top quality and aggressive selling price , we’ll be the market leader, be sure to don’t wait to get in touch with us by phone or email, should you be intrigued in almost any of our products.

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Quartz Mill, Quartz Powder Mill, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

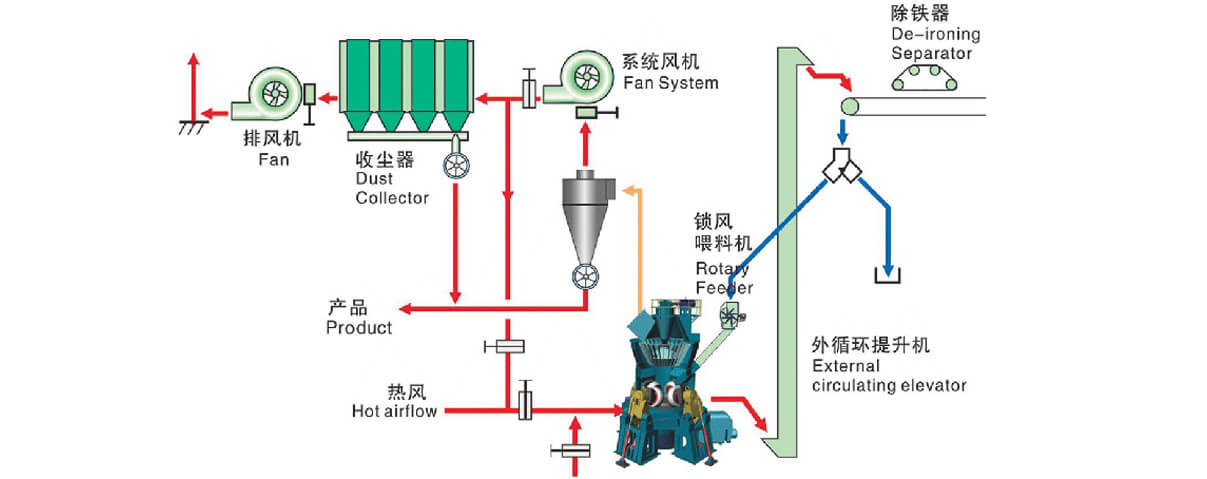

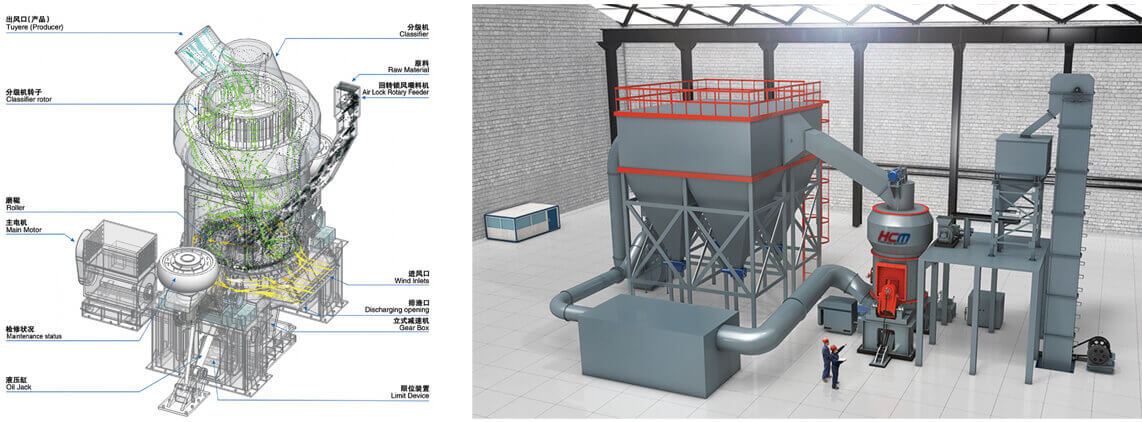

The motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and pulverized through squeezing, grinding and cutting. Simultaneously, the hot air is blew up around the dial and brow up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

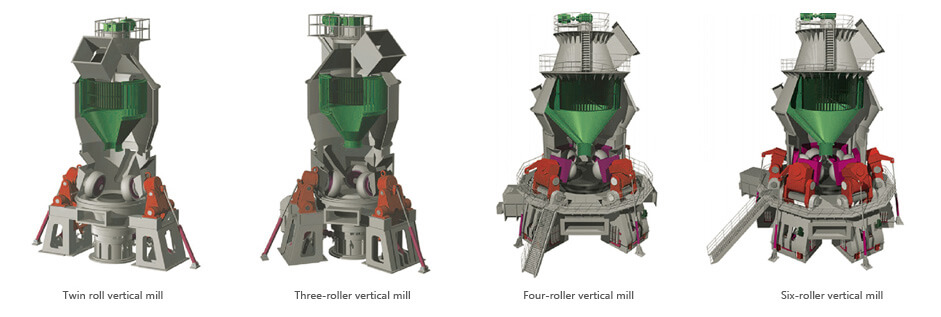

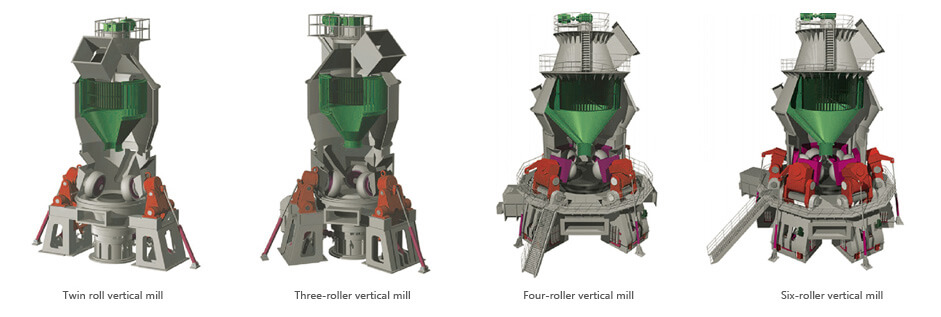

HLM vertical roller mill using standard modules to design and fabricate pressurization device. As the capacity increases, the roller numbers will increase (we can use 2, 3 or 4, maximum 6 rollers ) in proper permutation and combination to set different series of equipment with different capacities by minimum standard parts to meet the requirements of different materials, fineness and outputs.

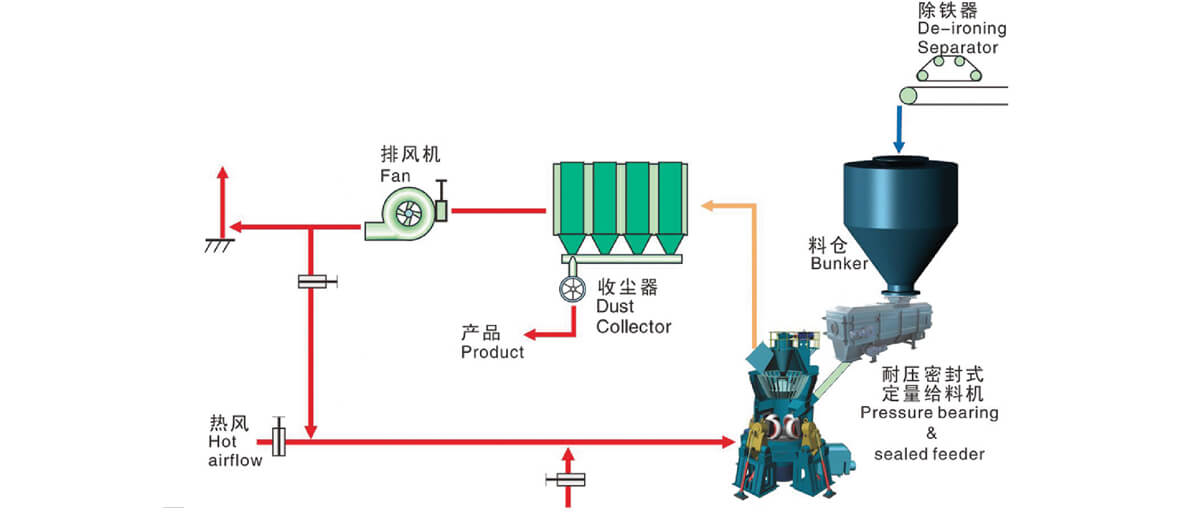

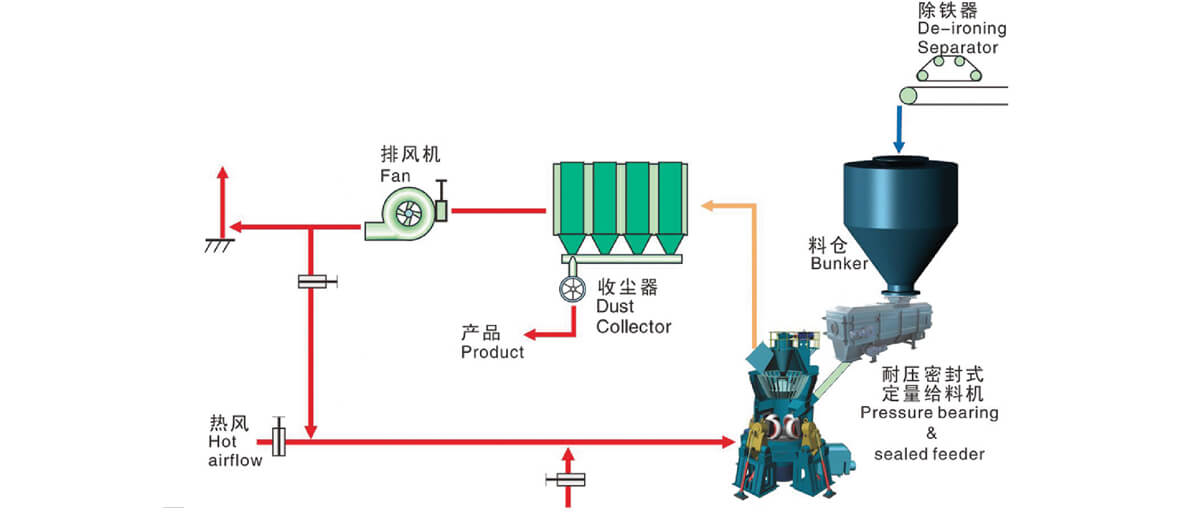

Unique Dust Collection System I

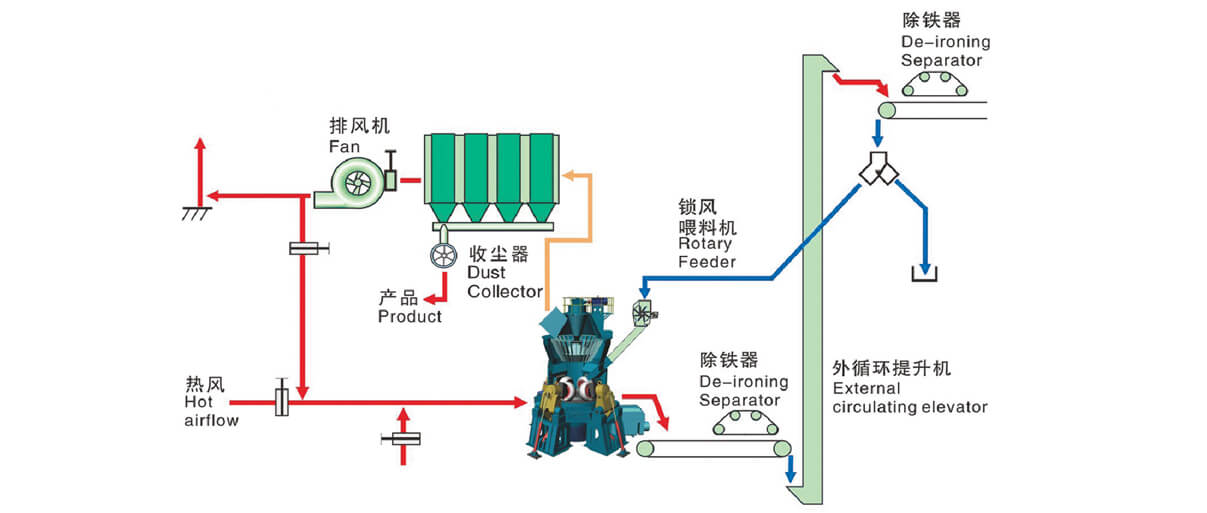

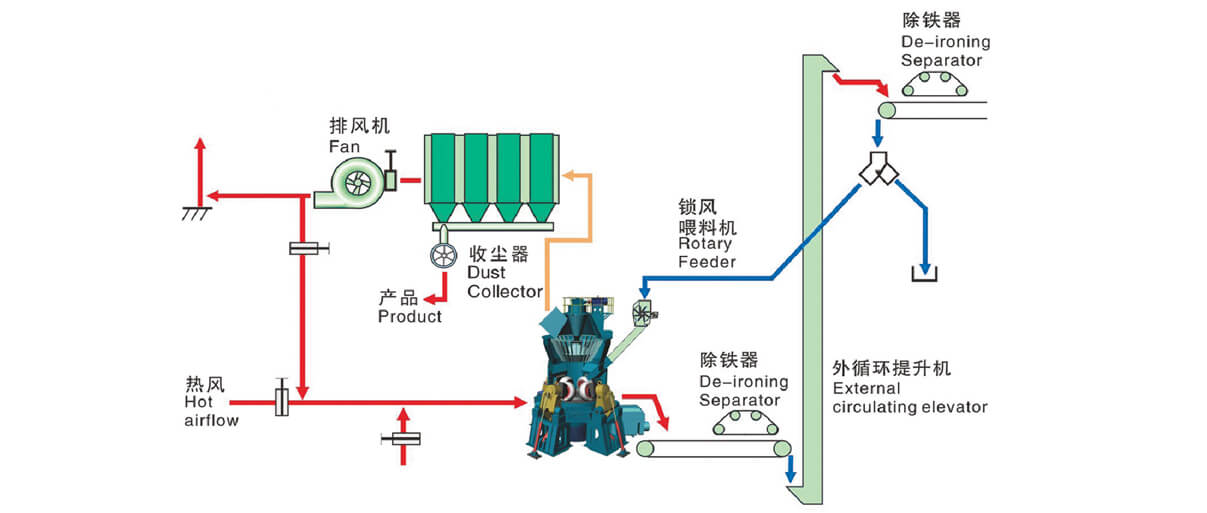

Single dust collection system II

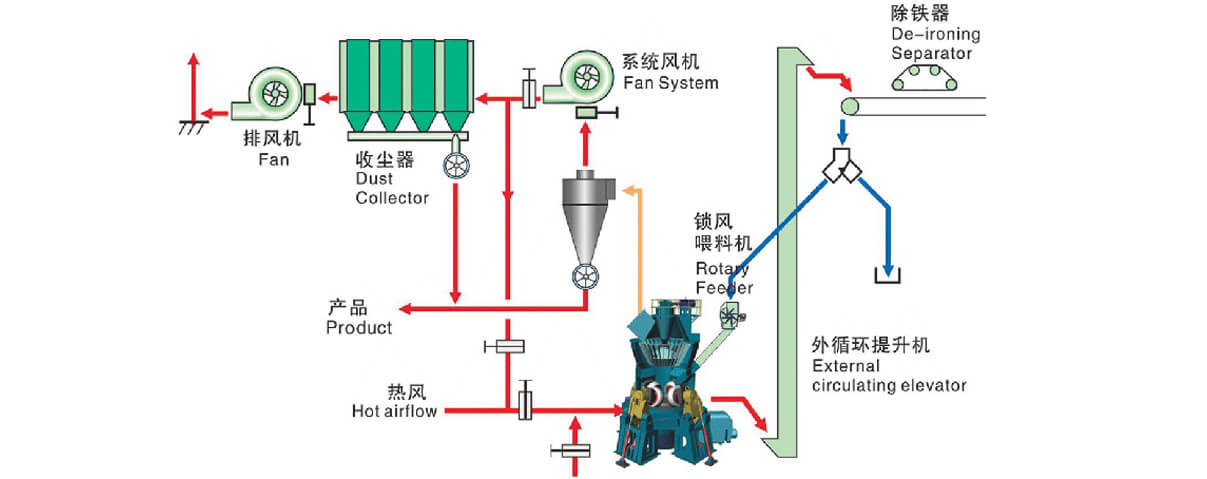

Secondary dust collection system

HLM vertical roller mill is able to process 200-325 fineness mesh mineral powder, users can adjust the mill to get different particle size, this vertical grinding mill has the multi-function of crushing, drying, grinding, and grading and conveying.

HLM vertical roller mill is able to process 200-325 fineness mesh mineral powder, users can adjust the mill to get different particle size, this vertical grinding mill has the multi-function of crushing, drying, grinding, and grading and conveying.

It is not only used for the production of quartz powder, but also can be used in slag, steel slag, tailings, fly ash, coal gangue, industrial by-product gypsum, construction waste, smelting waste residue, calcite, calcium carbonate, barite, manganese ore, dolomite, fluorite, coal, cement raw meal, clinker, limestone, bauxite, wollastonite and other minerals.

We would like to recommend you the optimal grinding mill model to ensure you get the desired grinding results. Please tell us the following questions:

1.Your raw material?

2.Required fineness(mesh/μm)?

3.Required capacity (t/h)?

HLM vertical roller mill is able to process 200-325 fineness mesh mineral powder, users can adjust the mill to get different particle size, this vertical grinding mill has the multi-function of crushing, drying, grinding, and grading and conveying.

HLM vertical roller mill is able to process 200-325 fineness mesh mineral powder, users can adjust the mill to get different particle size, this vertical grinding mill has the multi-function of crushing, drying, grinding, and grading and conveying.