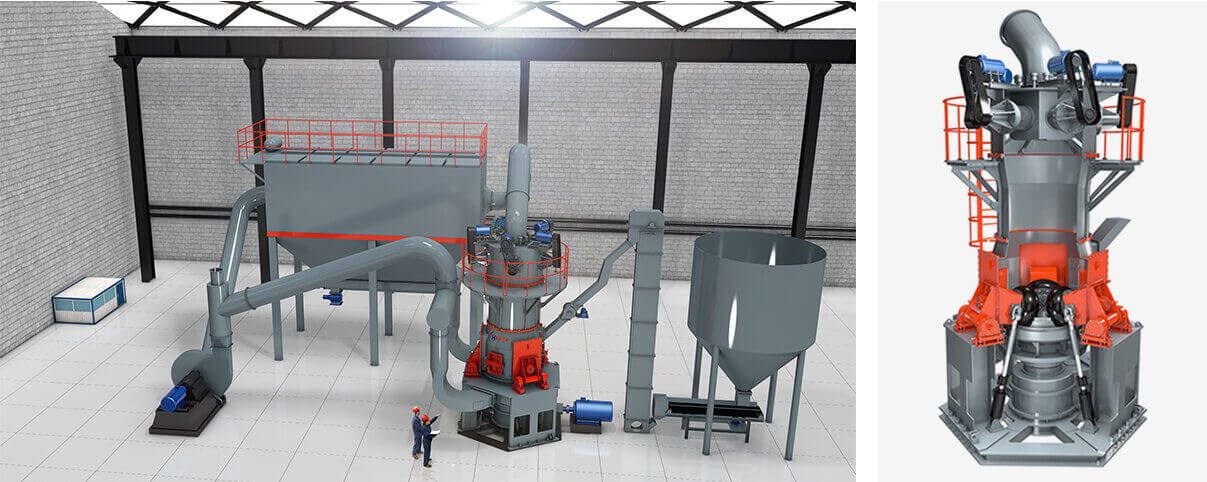

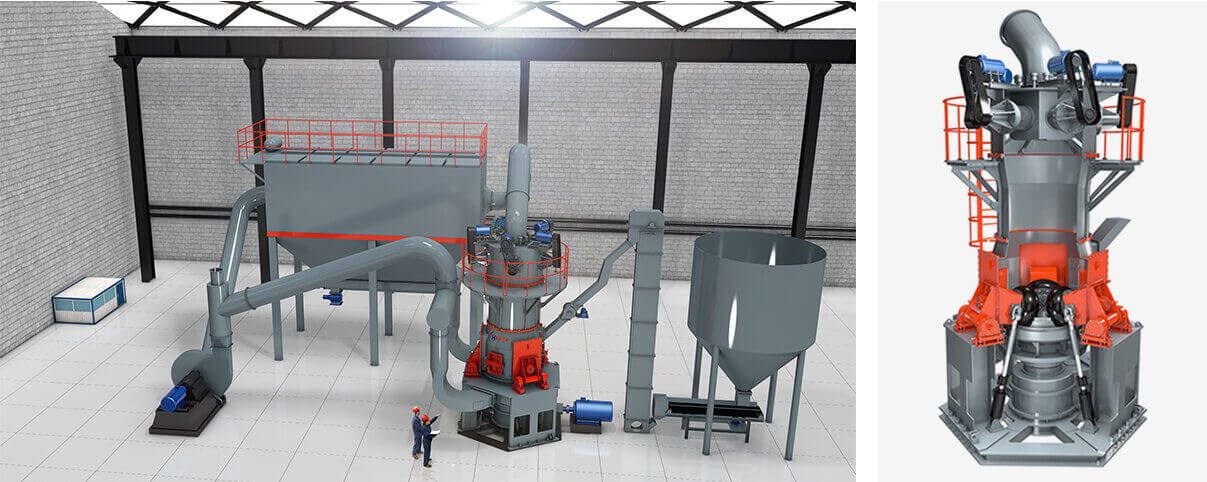

The motor drives the reducer to rotate the dial, the raw material are delivered to the center of the dial from the air lock rotary feeder. The material moves to the edge of the dial due to the effect of centrifugal force and than be ground by the force of the roller and smashed under extrusion, grinding and cutting. Simultaneously, the hot air is blew up around the dial and bring up the ground material. The hot air will dry the floating material and blow the coarse material back to the dial. The fine powder will be brought to the classifier, and then, the qualified fine powder will flow out the mill and be collected by dust collector, while the coarse powder will fall down to the dial by the blade of classifier and be ground again. This cycle is the whole process of grinding.

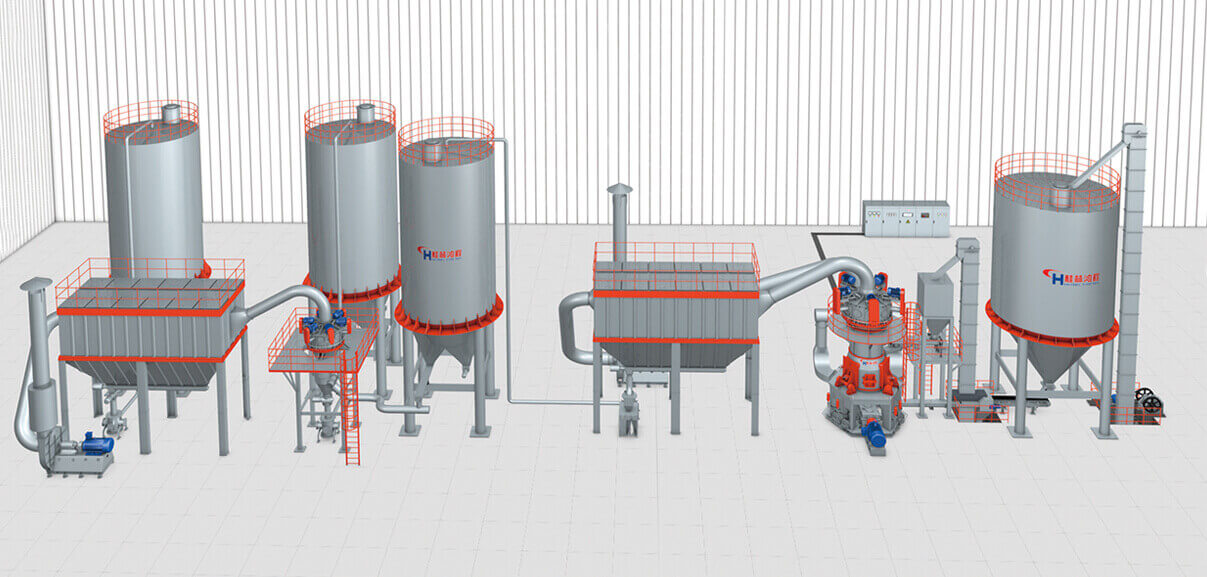

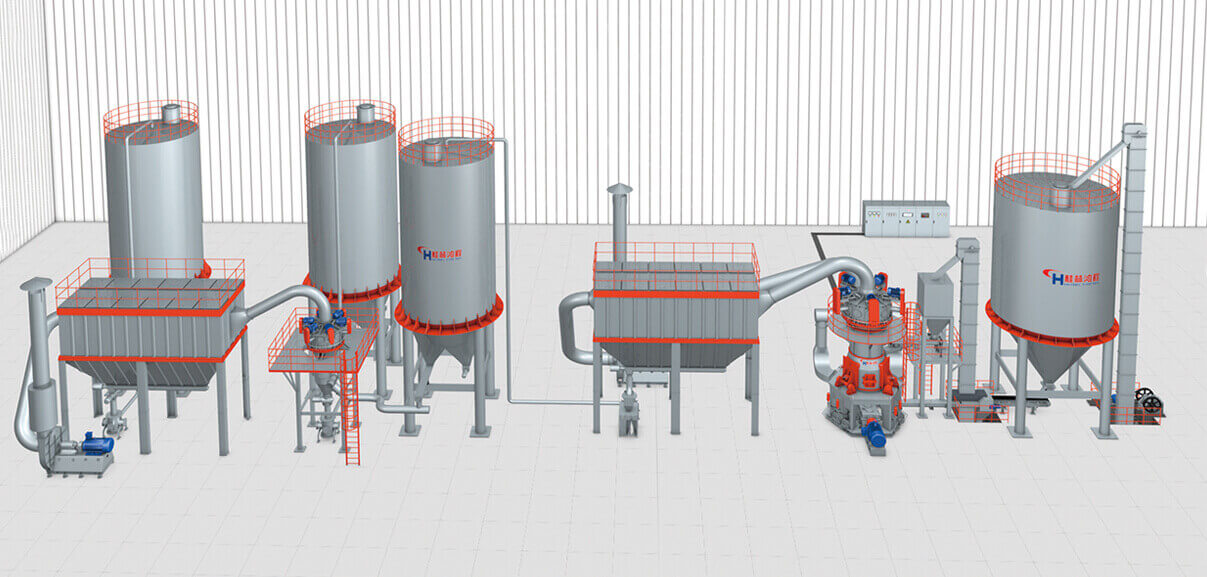

Secondary Classifying System

The secondary classifying system includes superfine classifier, fan, dust collector, hopper, screw conveyor and pipes. The classifier is the core machine of the whole system. HLMX series superfine vertical mill has equipped with the secondary classifier system, which is capable to efficiently separate coarse powder from fine powder to obtain products in different fineness between800 mesh to 2000 mesh.

Features of the secondary classifying system

High classifying efficiency: The classifier and the fan are controlled by frequency conversion speed regulation. By adjusting the speed of the classifier and fan impeller, various fineness of stable and reliable end product can be obtained rapidly. The classifying efficiency is high.

Classifier: A high efficient and energy saving powder separation device. Single rotor or multi-rotor is used to producing adjustable particle size due to the actual requirement.

Wide range of fineness: The classifying system is capable of selecting fine particles from the materials. The fineness can range from 800 mesh to 2000 mesh. With the secondary classifying system it can get different particles size, and it can also get same particle size in high throughput.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for factory customized High Yield Mill - HLMX Superfine Vertical Grinding Mill – HCM, The product will supply to all over the world, such as: Rome, Georgia, Israel, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.