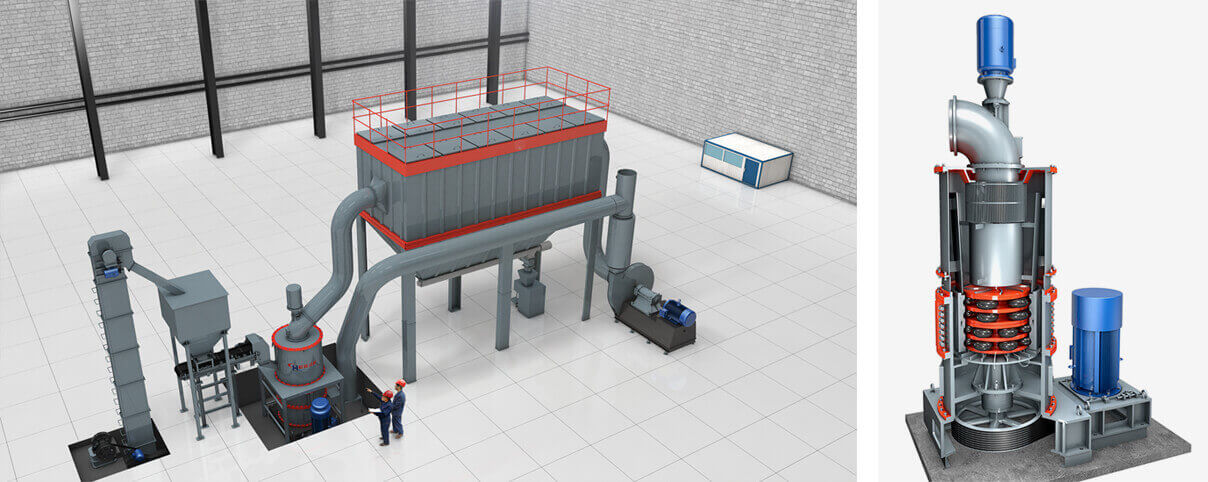

HCH ultrafine grinding mill consists of main mill, classifier, high pressure fan, cyclone collector, pipes, electromagnetic vibrating feeder, electrical distribution cabinet and etc.

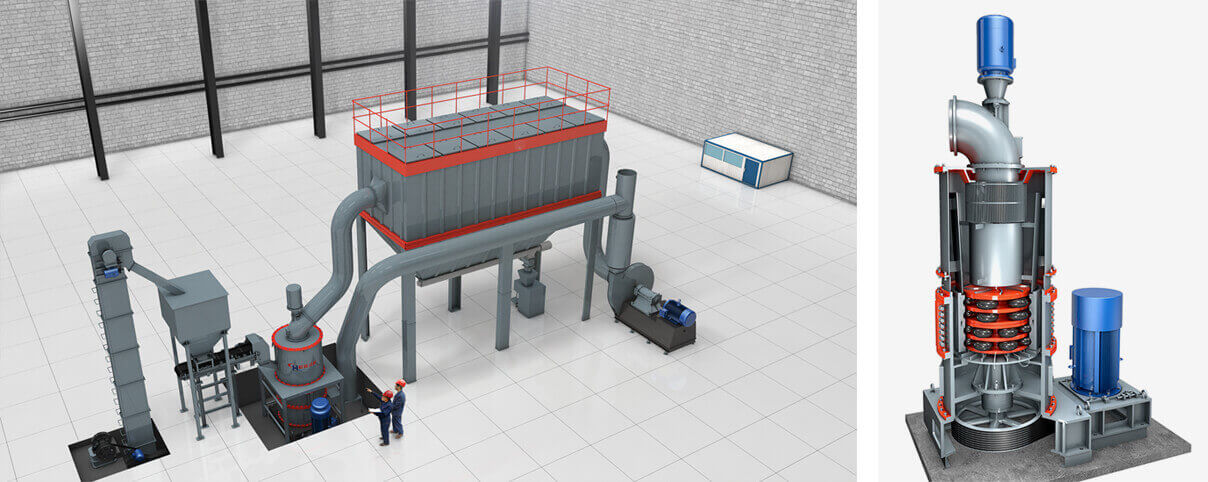

The large pieces of materials are crushed into small particles by the crusher and then sent to the storage bin by the elevator, and then sent to the tray on the turntable through the vibrating feeder and the inclined feeding pipe. The material is scattered to the periphery of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring, and then impacted, rolled, and ground by the ring roller, the powders become ultra-fine powder after three-layer ring processing. The high-pressure blower removes the external air through suction and bring the crushed material into the powder concentrator. The rotating impeller in the powder classifier makes the coarse materials fall back and be re-ground. The qualified fine powders enters the cyclone powder collector with the airflow and are discharged from the discharge valve at the lower part of the cyclone as the finished product.

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for factory customized Dolomite Ultrafine Grinding - HCH Ultrafine Grinding Mill – HCM, The product will supply to all over the world, such as: Zurich, Benin, Jordan, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.