Selelekela sa Mashala

Mashala ke mofuta oa liminerale tsa carbonized fossil.E hlophisitsoe ke khabone, haedrojene, oksijene, naetrojene le likarolo tse ling, tse ngata tse sebelisoang e le libeso ke batho.Hona joale, mashala a na le makhetlo a 63 a matla a polokelo ho feta petroleum.Mashala a ne a bitsoa khauta e ntšo 'me lijo tsa indasteri, ke matla a maholo ho tloha lekholong la bo18 la lilemo.Nakong ea Phetohelo ea Liindasteri, hammoho le ho qaptjoa le ho sebelisoa ha enjene ea mouoane, mashala a sebelisoa haholo e le mafura a indasteri 'me a tlisa matla a maholohali a tlhahiso sechabeng.

Tšebeliso ea Mashala

Mashala a Chaena a arotsoe ka lihlopha tse leshome.Ka kakaretso, mashala a mahlahahlaha, mashala a kolobisang, mashala a mafura, mashala a khase, a kopantsoeng ka mokhoa o fokolang, a sa kopanngoeng le a malelele a mollo ka kakaretso a bitsoa mashala a bituminous;Leshala le omeletseng le bitsoa semi Anthracite;Haeba litaba tse sa tsitsang li feta 40%, li bitsoa lignite.

Tafole ea likarolo tsa mashala (haholo-holo ho pheha mashala)

| Sehlopha | Leshala le bonolo | Mashala a fokolang | Leshala le omeletseng | Ho pheha leshala | Mashala a mafura | Mashala a khase | Leshala le fokolang la tlamo | Mashala a se nang tlamo | Leshala le lelelele la lelakabe | Leshala le sootho |

| Ho hloka botsitso | 0~10 | > 10 ~ 20 | > 14 ~ 20 | 14-30 | 26-37 | >30 | >20–37 | >20–37 | >37 | >40 |

| Litšobotsi tsa cinder | / | 0(phofo) | 0(liboloko) 8~20 | 12-25 | 12-25 | 9-25 | 0(maboloko)~9 | 0(phofo) | 0~5 | / |

Lignite:

Boholo bo boholo, bo sootho bo lefifi, bo khanyang, bo hlephileng;E na le hoo e ka bang 40% ea lintho tse feto-fetohang, sebaka se tlaase sa ho tima le ho chesoa habonolo.Ka kakaretso e sebelisoa indastering ea liquefaction, boiler ea matla, joalo-joalo.

Mashala a bituminous:

Ka kakaretso e na le granular, e nyane ebile e le phofo, haholo-holo e ntšo ebile e benya, e na le sebopeho se setle, e nang le lintho tse fetang 30% tse sa tsitsang, ntlha e tlaase ea ho tima ebile e bonolo ho e hotetsa;Mashala a mangata a bituminous a khomarela 'me a le bonolo ho senya nakong ea mollo.E sebelisoa indastering ea ho pheha, ho kopanya mashala, boiler ea matla le indasteri ea khase.

Anthracite:

Ho na le mefuta e 'meli ea phofo le likotoana tse nyane, tse ntšo, tsa tšepe le tse benyang.litšila tse fokolang, sebopeho se kopaneng, khabone e phahameng e tsitsitseng, ho fihlela ho feta 80%;Likahare tse sa tsitsang li tlase, ka tlase ho 10%, sebaka sa ho tima se phahame, 'me ha ho bonolo ho tšoara mollo.Palo e nepahetseng ea mashala le mobu li tla eketsoa bakeng sa ho tuka ho fokotsa matla a mollo.E ka sebelisoa ho etsa khase kapa ka ho toba e le mafura.

Mokhoa oa ho phalla ha mashala

Bakeng sa ho sila ha mashala, haholo-holo e thehiloe ho coefficient ea eona ea Harzburg grindability.Ha Harzburg e ntse e le khōloanyane ea ho sila, ho sila ho molemo (≥ 65), 'me e nyenyane ea Harzburg grindability coefficient, ho thata haholo ho sila (55-60).

Maikutlo:

① khetha mochini o ka sehloohong ho latela sephetho le litlhoko tsa botle;

② Sesebelisoa sa mantlha: mashala a futhumetseng a pholileng

Tlhahlobo ea mefuta ea ho sila

1. Leloala la pendulum (HC, HCQ letoto la leloala le thuntseng mashala):

Theko e tlase ea matsete, tlhahiso e phahameng, tšebeliso e tlase ea matla, lisebelisoa tse tsitsitseng le lerata le tlase;Bothata ke hore litšenyehelo tsa ts'ebetso le tlhokomelo li phahametse tsa leloala le otlolohileng.

Tafole ea bokhoni ea leloala la ho sila la HC (200 mesh D90)

|

| HC1300 | HC1700 | HC2000 |

| Bokhoni (t/h) | 3-5 | 8-12 | 15-20 |

| Enjene e kholo ea leloala (kw) | 90 | 160 | 315 |

| Motlakase oa motlakase (kw) | 90 | 160 | 315 |

| Enjene ea sehlopha (kw) | 15 | 22 | 75 |

Maikutlo (sebopeho sa mantlha):

① Sistimi e bulehileng ea patente ea Hongcheng e amoheloa bakeng sa mashala a mollo a lignite le a malelele a nang le botsitso bo phahameng.

② Thepa ea palesa ea plum e nang le pendulum e otlolohileng e amohela sebopeho sa matsoho, se nang le phello e ntle.

③ Sesebelisoa sa bopaki ba ho phatloha se etselitsoe sistimi.

④ Mokelli oa lerōle le lipeipi li tla etsoa ho qoba ho bokellana ha lerōle ka hohle kamoo ho ka khonehang.

⑤ Bakeng sa tsamaiso ea phofshoana, ho kgothaletswa hore bareki ba amohele phetisetso ya kgase mme ba kenye ka ho ya ka maemo a ho fetisa naetrojene le sistimi ya ho bona nitric oxide.

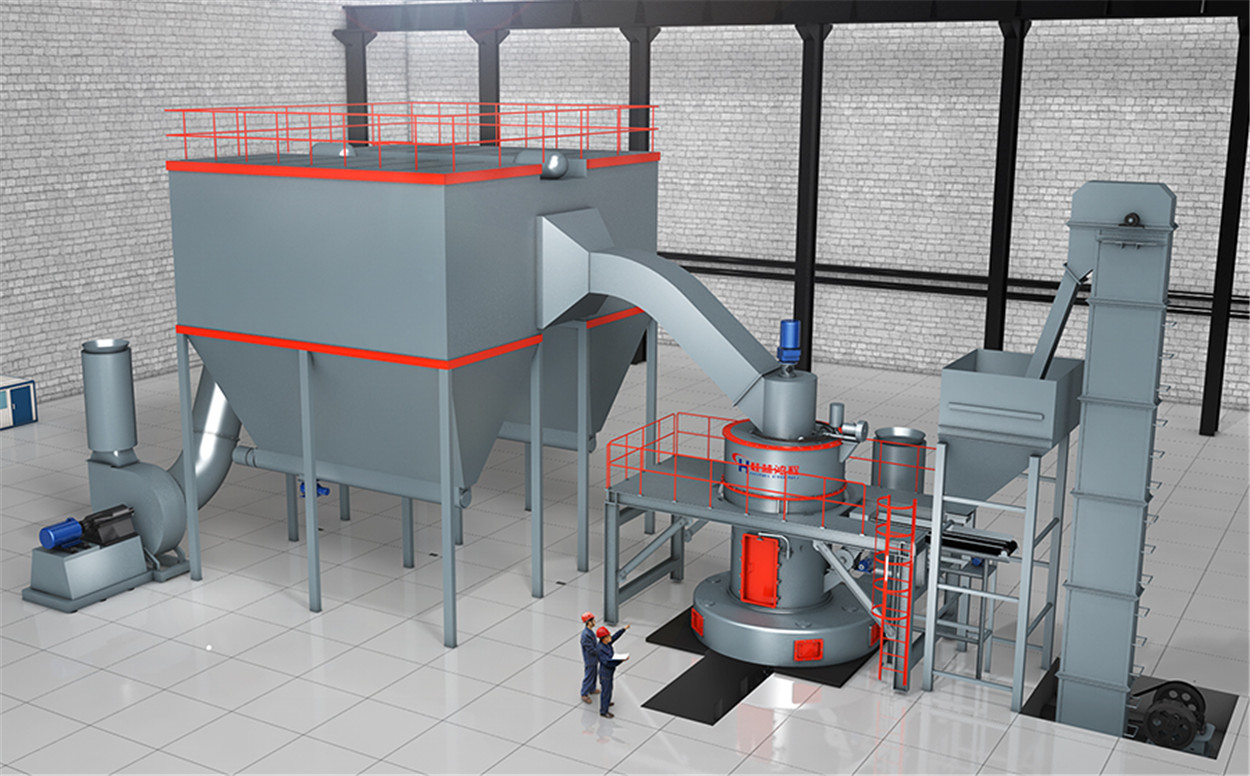

2. Leloala le otlolohileng la mashala (HLM e thethehileng ea mashala):

Tlhahiso e phahameng, tlhahiso e kholo, tekanyo e tlaase ea tlhokomelo, tekanyo e phahameng ea boits'oaro le theknoloji ea moea o chesang o butsoitseng.Bobebe ke litšenyehelo tse phahameng tsa matsete le sebaka se seholo sa fatše.

Litlhaloso le litekanyetso tsa tekheniki tsa HLM e hahelletsoeng ka mashala a otlolohileng (indasteri ea metallurgic)

| Mohlala | Tlhaloso: HLM1300MF | Tlhaloso: HLM1500MF | Tlhaloso: HLM1700MF | Tlhaloso: HLM1900MF | Lethathamo la HLM2200MF | Lethathamo la HLM2400MF | Tlhaloso: HLM2800MF |

| Bokhoni (t/h) | 13-17 | 18-22 | 22-30 | 30-40 | 40-50 | 50-70 | 70-100 |

| Mongobo oa lintho tse bonahalang | ≤15% | ||||||

| Bokhabane ba sehlahisoa | D80 | ||||||

| Mongobo oa sehlahisoa | ≤1% | ||||||

| Matla a motlakase (kw) | 160 | 250 | 315 | 400 | 500 | 630 | 800 |

Mothati oa I:Cho potlaka ha thepa e tala

E kholoanyaneMashalathepa e silakanngoa ke crusher ho phepelo fineness (15mm-50mm) tse ka kenang leloala sila.

SethalaII: Grinding

E sithabetsengMashalalisebelisoa tse nyenyane li romeloa ho hopper ea polokelo ka lifti, ebe li romelloa ka kamoreng ea ho sila ea leloala ka mokhoa o lekanang le ka bongata ka ho fepa bakeng sa ho sila.

Mothati oa III:Hlophisang

Lisebelisoa tse sililoeng li hlophisoa ka mokhoa oa ho hlophisa, 'me phofo e sa tšoaneleheng e kenngoa ke sehlopha sa lihlopha ebe e khutlisetsoa mochine o moholo bakeng sa ho sila hape.

SethalaV: Cho bokella lihlahisoa tse felileng

Phofo e tsamaellanang le khase e phalla ka har'a phaephe e nang le khase 'me e kena ka har'a pokello ea lerōle bakeng sa ho arohana le ho bokella.Phofo e felileng e bokelletsoeng e romelloa ho silo ea sehlahisoa se felileng ka sesebelisoa se fetisang ka boema-kepe ba ho lahla, ebe se pakoa ke tanka ea phofo kapa sephutheloana sa othomathiki.

Mehlala ea kopo ea ts'ebetso ea phofo ea mashala

Mohlala le palo ea thepa ena: 3 disete tsa HC1700 bula tsamaiso ea potoloho sila Mills

Ho sebetsa thepa e tala: Anthracite

Bokhabane ba sehlahisoa se felileng: 200 mesh D92

Thepa Bokhoni: 8-12 lithane / hora

Morero ke ho fana ka mashala a hloekisitsoeng bakeng sa boiler e chesitsoeng ka mashala ea sistimi e futhumatsang ka tlas'a lefatše morafong oa mashala oa Bulianta oa sehlopha.Mokonteraka ea akaretsang oa morero ona ke China Academy of Coal Sciences.Ho tloha ka 2009, Chinese Academy of Coal Sciences e bile molekane oa maano oa Hongcheng le selekane se matla.Li-boiler tsohle tse chesitsoeng ka mashala le merero ea mashala a silafalitsoeng li amohela leloala la ho sila la Hongcheng bakeng sa ho tsamaisana le sistimi.Lilemong tse 6 tse fetileng, Hongcheng e sebelisane 'moho ka tieo le Academy of Coal Sciences,' me merero ea ho hloekisa mashala e hasane hohle libakeng tse ka sehloohong tse hlahisang mashala Chaena.Morero o amohela lihlopha tse tharo tsa limilone tsa Raymond tse nang le sistimi e bulehileng ea HC1700, e etselitsoeng ka ho khetheha ho sila mashala a kolobisitsoeng.Hc1700 pulverized leloala le silang le amohela potoloho e bulehileng, ho kenya sesebelisoa sa bopaki ba ho phatloha le mehato e meng, 'me sistimi e bolokehile ebile e ka tšeptjoa.Tlhahiso ea leloala la HC1700 e phahame ka 30-40% ho feta ea leloala la setso la pendulum, le bolokang matla le tikoloho.

Nako ea poso: Oct-22-2021