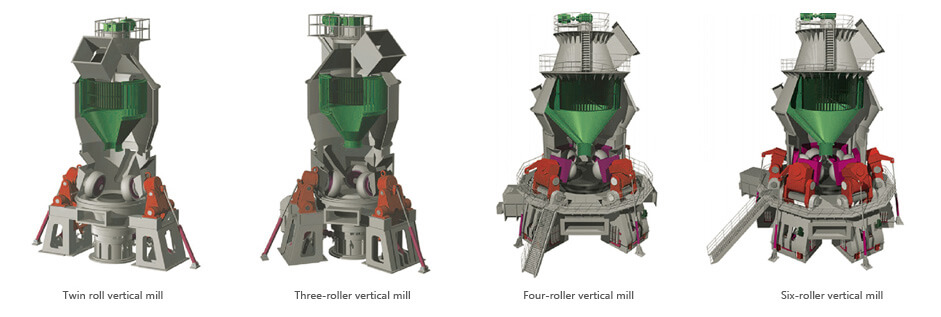

Alaabada ugu dambeysa waxay leedahay tayo xasilloon.Waqtiga gaaban ee alaabta dhulka la dhigo waxay hubin kartaa xitaa qaabka qayb iyo dareere aad u fiican.Inta yar ee ka kooban birta waa ay fududahay in la saaro si loo dammaanad qaado cadaanka sare iyo nadiifnimada.

faham

U BAAHAN XAL?Wixii macluumaad dheeraad ah oo shiididda ama codsiga xigashada fadlan nala soo xiriir.

Weydiinnala soo xiriir

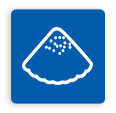

Ku soo dhawoow Guilin HongchengGuilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Taleefanka:86-0773-3568321

- Cinwaanka:Beerta Warshadaha ee Yangtang Shanshui, Aagga Horumarinta Dhaqaalaha ee Xicheng, Guilin City, Gobolka Guangxi, Shiinaha

- Iimayl:hcmkt@hcmilling.com

© Xuquuqda daabacaadda - 2010-2023: Dhammaan xuquuqaha way xifdisan yihiin.Alaabooyinka Kulul - Khariidadda goobta

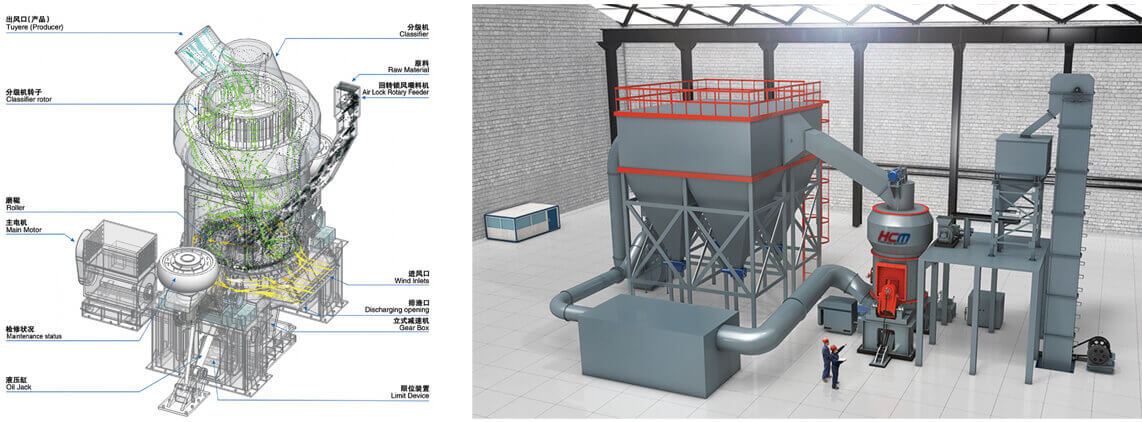

Batroolka Coke Roller Mill, Ultra Fine shiididda Mill, Shidida Dhuxusha, Furimaha Dagaalka, Ultra Fine Mill, Warshada Rinjiga Burada Shiida ee Ka timid Shiineeska Soo-saare,

Batroolka Coke Roller Mill, Ultra Fine shiididda Mill, Shidida Dhuxusha, Furimaha Dagaalka, Ultra Fine Mill, Warshada Rinjiga Burada Shiida ee Ka timid Shiineeska Soo-saare,